Other Parts Discussed in Thread: C2000WARE, TMS320F2800157

Tool/software:

Hello,

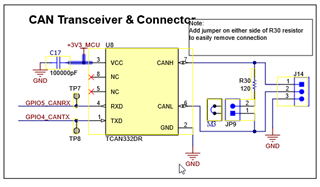

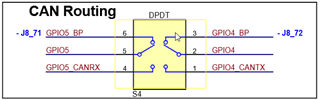

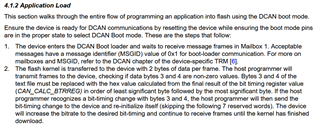

We are attempting to flash a LAUNCHXL-F2800157 LaunchPad via CAN using the DCAN Flash Programmer utility from C2000Ware, but experiencing communication issues. Here are the details:

Setup:

MCU: TMS320F2800157

CAN Interface: Peak PCAN USB Pro

Project Path: C:\ti\c2000\C2000Ware_5_04_00_00\utilities\flash_programmers\dcan_flash_programmer\dcan_flash_programmer

Issue:

The Peak USB Pro's status LED is blinking red during transmission attempts, suggesting communication errors. We have reviewed the configuration but uncertain about the optimal settings.

Current Configuration in dcan_flash_programmer.cpp:

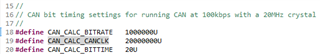

// Bitrate configuration

bitrate = "f_clock_mhz = 20, nom_brp = 40, nom_tseg1 = 16, nom_tseg2 = 3, nom_sjw = 2"; // 100kbps

// Initialization

gStatus = CAN_Initialize(PCAN_USBBUS1, PCAN_BAUD_100K);

// Sleep timing for F280015x

sleep_time = 10; // in milliseconds

Questions:

- Are these bit timing parameters appropriate for the F2800157?

- Is the current sleep_time of 10ms appropriate for the F2800157, or should it be adjusted?

- I also came across the following function in

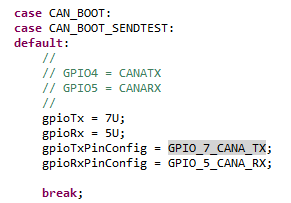

flash_kernel_ex5_dcan_flash_kernel.c:

EntryAddr = DCAN_Boot(CAN_BOOT_SENDTEST, 0, 1, 20,

WE_Protection_A_Mask, WE_Protection_B_Mask, WE_Protection_UO_Mask); I would like clarification on the correct parameters for EntryAddr in this function.Any guidance on resolving these communication issues would be greatly appreciated.

Additional Info:

Have verified proper physical connections and termination