Other Parts Discussed in Thread: SYSCONFIG, TMDXIDDK379D, DESIGNDRIVE

Tool/software:

Hello TI,

I’m build a 20kW Inverter for PMSM, which I have to test. I’m now looking for an MCU and control software.

Motor: ME1507 IPM

Encoder: Sin/Cos without index

Vmax = 50-70V

Imax = 300A

I worked a lot with Instaspin and the F28069. The easiest way for me I think would be to use this MCU and make a hardware for the Sin/Cos Encoder and just add the Sin/Cos library.

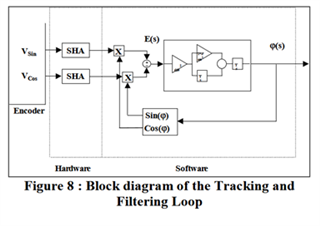

But if I want to use a newer MCU like the F28P65, F28388D or maybe F280039c, what would you suggest as starting point? I only need sensored-FOC (sensorless additionally is a nice to have). I also would like in this case use the POSMGR for the sin/cos interface.

That is what I found for the F28P65 which I would prefer as MCU:

1. tidm_02017_2w_traction_inverter. The code looks clear, but I didn’t find any mor precisely documentation about the code. Is there any? Does this code work properly? Here I would add the POSMGR initialization with the sysconfig tool right?

2. tida_010936_ganhfmd, tmdxiddk379d and servo_drive_with_can are DesignDrive based. I’ve never worked with DesignDrive, how difficult is it to get into this? Here I would add the POSMGR initialization in the source code?

Another idea would be to use Matlab or Plecs. For Matlab I found this, “Generate Motor Control Models for Selected Algorithm and Hardware”. I’ve worked with Matlab but never with the C2000 Blockset. Is it possible to add the POSMGR with Sin/Cos interface in this example? I found an example for the F280049c and the POSMGR for Matlab. Is it for the F28p65 also so easy to implement?

At the moment this is just for testing the inverter, a reliable implementation will be done later.

Any suggestions would be very nice, best regards,

Daniel