Tool/software:

Hello TI Team,

I am using the TMS320F28377S and trying to establish communication using the SPI module. I’ve been working on this for two days but haven’t been able to get it working properly.

When I write my own SPI communication functions without making any changes to the configuration, I am able to write and read data successfully.

The device I am trying to communicate with is an EEPROM chip: 25LC640A-E/SN. Could you please help me with this?

Below are the pin assignments and the code I have prepared.

(Nonfunctional)

void SPI_GPIO_Init(void)

{

EALLOW;

// === MOSI: GPIO24 → SPISIMOB ===

GpioCtrlRegs.GPAGMUX2.bit.GPIO24 = 1; // Set GPIO24 to use GMUX option 1

GpioCtrlRegs.GPAMUX2.bit.GPIO24 = 2; // Set MUX to 2 for SPISIMOB function

GpioCtrlRegs.GPAQSEL2.bit.GPIO24 = 3;

// === MISO: GPIO25 → SPISOMIB ===

GpioCtrlRegs.GPAGMUX2.bit.GPIO25 = 1; // Set GPIO25 to use GMUX option 1

GpioCtrlRegs.GPAMUX2.bit.GPIO25 = 2; // Set MUX to 2 for SPISOMIB function

GpioCtrlRegs.GPAQSEL2.bit.GPIO25 = 3;

// === CLK: GPIO26 → SPICLKB ===

GpioCtrlRegs.GPAGMUX2.bit.GPIO26 = 1; // Set GPIO26 to use GMUX option 1

GpioCtrlRegs.GPAMUX2.bit.GPIO26 = 2; // Set MUX to 2 for SPICLKB function

GpioCtrlRegs.GPAQSEL2.bit.GPIO26 = 3;

// === Set GPIO directions ===

GpioCtrlRegs.GPADIR.bit.GPIO24 = 1; // MOSI: output

GpioCtrlRegs.GPADIR.bit.GPIO25 = 0; // MISO: input

GpioCtrlRegs.GPADIR.bit.GPIO26 = 1; // CLK: output

// === Enable internal pull-up resistors ===

GpioCtrlRegs.GPAPUD.bit.GPIO24 = 0; // Enable pull-up for MOSI

GpioCtrlRegs.GPAPUD.bit.GPIO25 = 0; // Enable pull-up for MISO

GpioCtrlRegs.GPAPUD.bit.GPIO26 = 0; // Enable pull-up for CLK

GpioCtrlRegs.GPBMUX1.bit.GPIO38 = 0; // Set GPIO38 to GPIO function

GpioCtrlRegs.GPBDIR.bit.GPIO38 = 1; // Set as output

GpioCtrlRegs.GPBPUD.bit.GPIO38 = 0; // Enable pull-up resistor

GpioDataRegs.GPBSET.bit.GPIO38 = 1; // Set HIGH initially (inactive)

EDIS;

}

void SPI_INIT()

{

EALLOW;

GpioDataRegs.GPBSET.bit.GPIO38 = 1; // nCS HIGH

CpuSysRegs.PCLKCR8.bit.SPI_B = 1;

SpibRegs.SPICCR.bit.SPISWRESET = 0; // Reset SPI

SpibRegs.SPICCR.bit.CLKPOLARITY = 0; // Clock polarity 0

SpibRegs.SPICTL.bit.CLK_PHASE = 0 ;

SpibRegs.SPICCR.bit.SPICHAR = 7; // 8-bit data

SpibRegs.SPICTL.bit.MASTER_SLAVE = 1; // Master mode

SpibRegs.SPICTL.bit.TALK = 1; // TX enable

SpibRegs.SPIBRR.bit.SPI_BIT_RATE = 21; // Baud Rate

SpibRegs.SPICCR.bit.SPISWRESET = 1; // Release SPI from reset

EDIS;

}

void EEPROM_WriteByte(Uint16 address, Uint8 data)

{

// Write Enable

GpioDataRegs.GPBCLEAR.bit.GPIO38 = 1; // nCS LOW

SPIB_SendByte(0x06); // Write Enable opcode

GpioDataRegs.GPBSET.bit.GPIO38 = 1; // nCS HIGH

// Write Command

SPI_Delay();

GpioDataRegs.GPBCLEAR.bit.GPIO38 = 1;

SPIB_SendByte(0x02); // WRITE opcode

SPIB_SendByte((address >> 8) & 0xFF); // Address High Byte

SPIB_SendByte(address & 0xFF); // Address Low Byte

SPIB_SendByte(data); // Data byte

GpioDataRegs.GPBSET.bit.GPIO38 = 1;

DELAY_US(5000); // Wait write cycle (max 5ms)

}

Uint8 EEPROM_ReadByte(Uint16 address)

{

Uint8 value;

GpioDataRegs.GPBCLEAR.bit.GPIO38 = 1;

SPIB_SendByte(0x03); // READ opcode

SPIB_SendByte((address >> 8) & 0xFF); // Address High Byte

SPIB_SendByte(address & 0xFF); // Address Low Byte

value = SPIB_SendByte(0x00); // Dummy write to receive data

DELAY_US(5);

GpioDataRegs.GPBSET.bit.GPIO38 = 1;

return value;

}

Uint16 SPIB_SendByte(Uint16 data)

{

while (SpibRegs.SPISTS.bit.BUFFULL_FLAG == 1); // Wait if TX buffer full

SpibRegs.SPITXBUF = data << 8;

while (SpibRegs.SPISTS.bit.INT_FLAG == 0); // Wait for RX

return SpibRegs.SPIRXBUF & 0x00FF;

}

void SPI_Delay(void)

{

asm(" RPT #50 || NOP");

}

I tested in the main loop

void main(void)

{

for(;;)

{

if(spi_write_test==1)

{

EEPROM_WriteByte(0x1234, 0xAA);

spi_write_test=0;

}

if(spi_read_test==1)

{

EEPROM_ReadByte(0x1234);

spi_read_test=0;

}

}

}

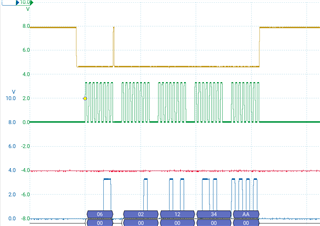

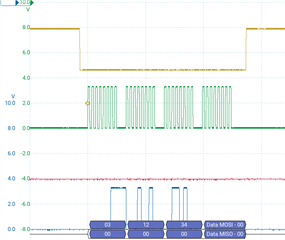

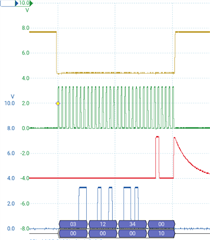

Clock Frequency --> 750kHz

Write sequence

Read Sequence

(Functional)

void SPI_GPIO_Init(void)

{

EALLOW;

// MOSI (Master Out, Slave In) -> GPIO24

GpioCtrlRegs.GPAMUX2.bit.GPIO24 = 0; // Set as GPIO

GpioCtrlRegs.GPADIR.bit.GPIO24 = 1; // Configure as output

// MISO (Master In, Slave Out) -> GPIO25

GpioCtrlRegs.GPAMUX2.bit.GPIO25 = 0; // Set as GPIO

GpioCtrlRegs.GPADIR.bit.GPIO25 = 0; // Configure as input

// CLK (Clock) -> GPIO26

GpioCtrlRegs.GPAMUX2.bit.GPIO26 = 0; // Set as GPIO

GpioCtrlRegs.GPADIR.bit.GPIO26 = 1; // Configure as output

// CS (Chip Select) -> GPIO38

GpioCtrlRegs.GPBMUX1.bit.GPIO38 = 0; // Set as GPIO

GpioCtrlRegs.GPBDIR.bit.GPIO38 = 1; // Configure as output

EDIS;

}

void SPI_Delay(void)

{

asm(" RPT #50 || NOP"); // Short delay between clock transitions

}

void SPI_SendByte(uint8_t data)

{

int i;

for (i = 7; i >= 0; i--)

{

if ((data >> i) & 0x01)

GpioDataRegs.GPASET.bit.GPIO24 = 1; // MOSI high

else

GpioDataRegs.GPACLEAR.bit.GPIO24 = 1; // MOSI low

SPI_Delay();

GpioDataRegs.GPASET.bit.GPIO26 = 1; // CLK high

SPI_Delay();

GpioDataRegs.GPACLEAR.bit.GPIO26 = 1; // CLK low

SPI_Delay();

}

}

uint8_t SPI_ReadByte(void)

{

int i;

uint8_t received = 0;

for (i = 7; i >= 0; i--)

{

// Dummy 0 bit on MOSI

GpioDataRegs.GPACLEAR.bit.GPIO24 = 1;

SPI_Delay();

GpioDataRegs.GPASET.bit.GPIO26 = 1; // CLK high

SPI_Delay();

// Sample MISO

if (GpioDataRegs.GPADAT.bit.GPIO25)

received |= (1 << i);

GpioDataRegs.GPACLEAR.bit.GPIO26 = 1; // CLK low

SPI_Delay();

}

return received;

}

void EEPROM_Write_0x1234_0x10(void)

{

// Step 1: Send WREN command (Write Enable)

GpioDataRegs.GPBCLEAR.bit.GPIO38 = 1; // CS low

SPI_SendByte(0x06); // WREN command

GpioDataRegs.GPBSET.bit.GPIO38 = 1; // CS high

SPI_Delay(); // Small delay if needed

// Step 2: Send WRITE command + Address + Data

GpioDataRegs.GPBCLEAR.bit.GPIO38 = 1; // CS low

SPI_SendByte(0x02); // WRITE command

SPI_SendByte(0x12); // Address MSB (0x12 for 0x1234)

SPI_SendByte(0x34); // Address LSB (0x34 for 0x1234)

SPI_SendByte(0xAA); // Data byte (0x10)

GpioDataRegs.GPBSET.bit.GPIO38 = 1; // CS high

// Step 3: Wait for write cycle to complete (typical 5ms)

DELAY_US(5000); // 5 milliseconds wait

}

uint8_t EEPROM_Read_0x1234(void)

{

uint8_t read_data;

GpioDataRegs.GPBCLEAR.bit.GPIO38 = 1; // CS low - start communication

SPI_SendByte(0x03); // READ command

SPI_SendByte(0x12); // Address MSB

SPI_SendByte(0x40); // Address LSB

read_data = SPI_ReadByte(); // Read one byte

GpioDataRegs.GPBSET.bit.GPIO38 = 1; // CS high - end communication

return read_data;

}

Main Loop

void main(void)

{

for(;;)

{

if(spi_write_test==1)

{

EEPROM_Write_0x1234_0x10();

spi_write_test=0;

}

if(spi_read_test==1)

{

EEPROM_Read_0x1234();

spi_read_test=0;

}

}

}

Write

Read

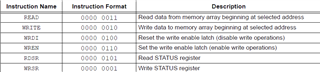

EEPROM Device command table