Hi,

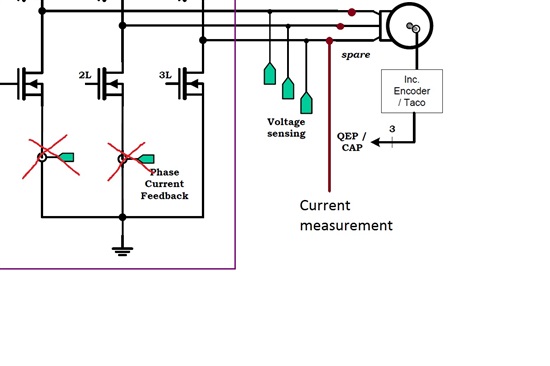

I use InstaSPIN FOC in my new design and I am trying to measure current with 3 Hall sensors.

My motor is: ACIM, 5,5kW

I define USER_IQ_FULL_SCALE_CURRENT_A, USER_ADC_FULL_SCALE_CURRENT_A, USER_IQ_FULL_SCALE_VOLTAGE_V, USER_ADC_FULL_SCALE_VOLTAGE_V correctly.

I didn't connect the sensors to transistors which are connected to the GND, but directly to the 3 phases of the motor.

So, I started the motor as it is explained in the PDF file but measured parameters of the identification are incorrect.

My question is what I have to define in the CCS program for correct current measurement?

Thank you!