Hi,

I am working on the Sensored FOC of PMSM on TI's TMDSHVMTRPFCKIT. I am using the example program provided by TI for running a PMS Motor provided by TI. I am successful in incrementally building upto the 3rd BUILDLEVEL of the software. However, at BUILDLEVEL 4, when lsw is set to 2 ( ie, when the speed is also controlled in a closed loop ) and the input voltage to the kit from a variac goes above 100 V, the motor initally jerks and then stops rotating.

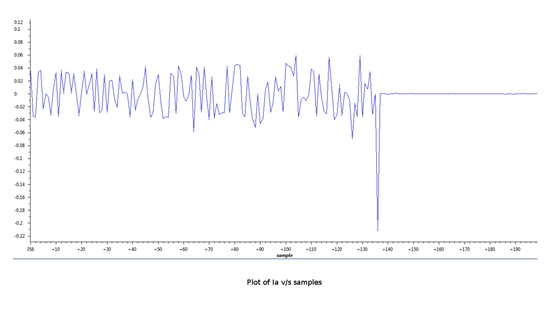

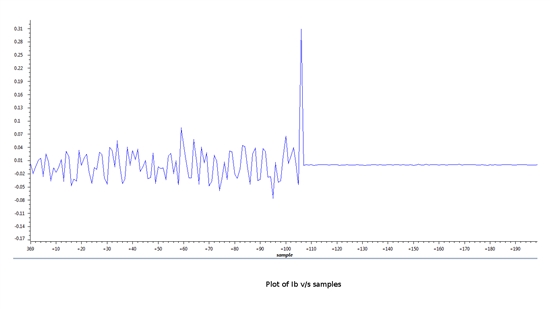

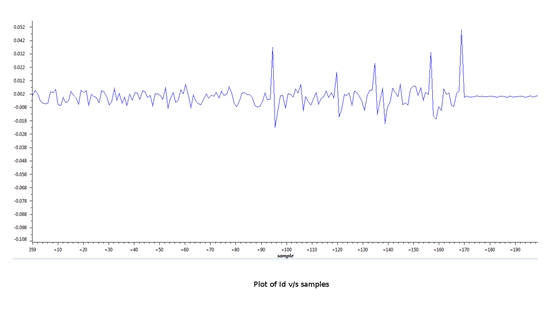

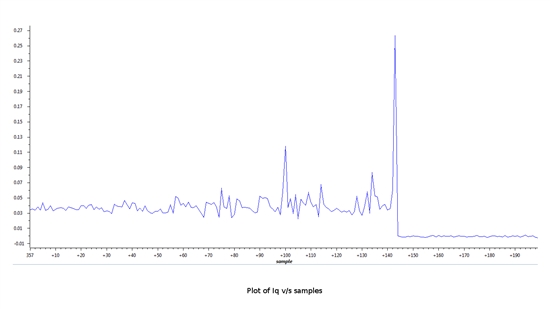

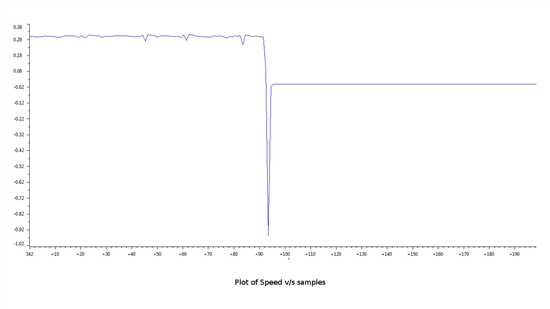

I am attaching real time plots of currents Ia, Ib, Id and Iq, of the Rawtheta value computed from QEP feedback as well as the plot of the Speed, which were obtained during the run time. Kindly analyse the plots and give me a solution to overcome this issue.