Other Parts Discussed in Thread: CONTROLSUITE, , POWERSUITE, TIDM-1001

Tool/software: Code Composer Studio

Hello there

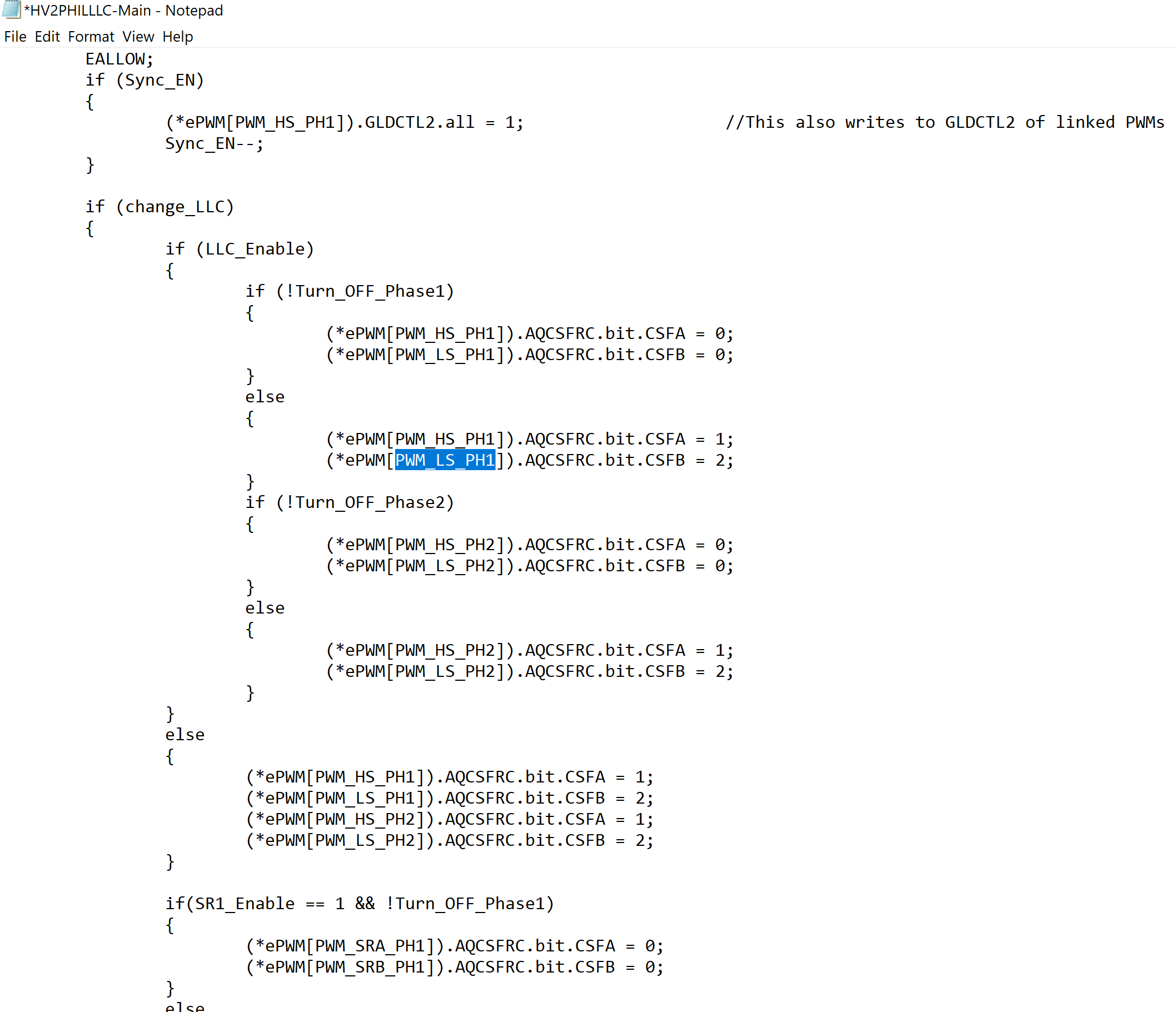

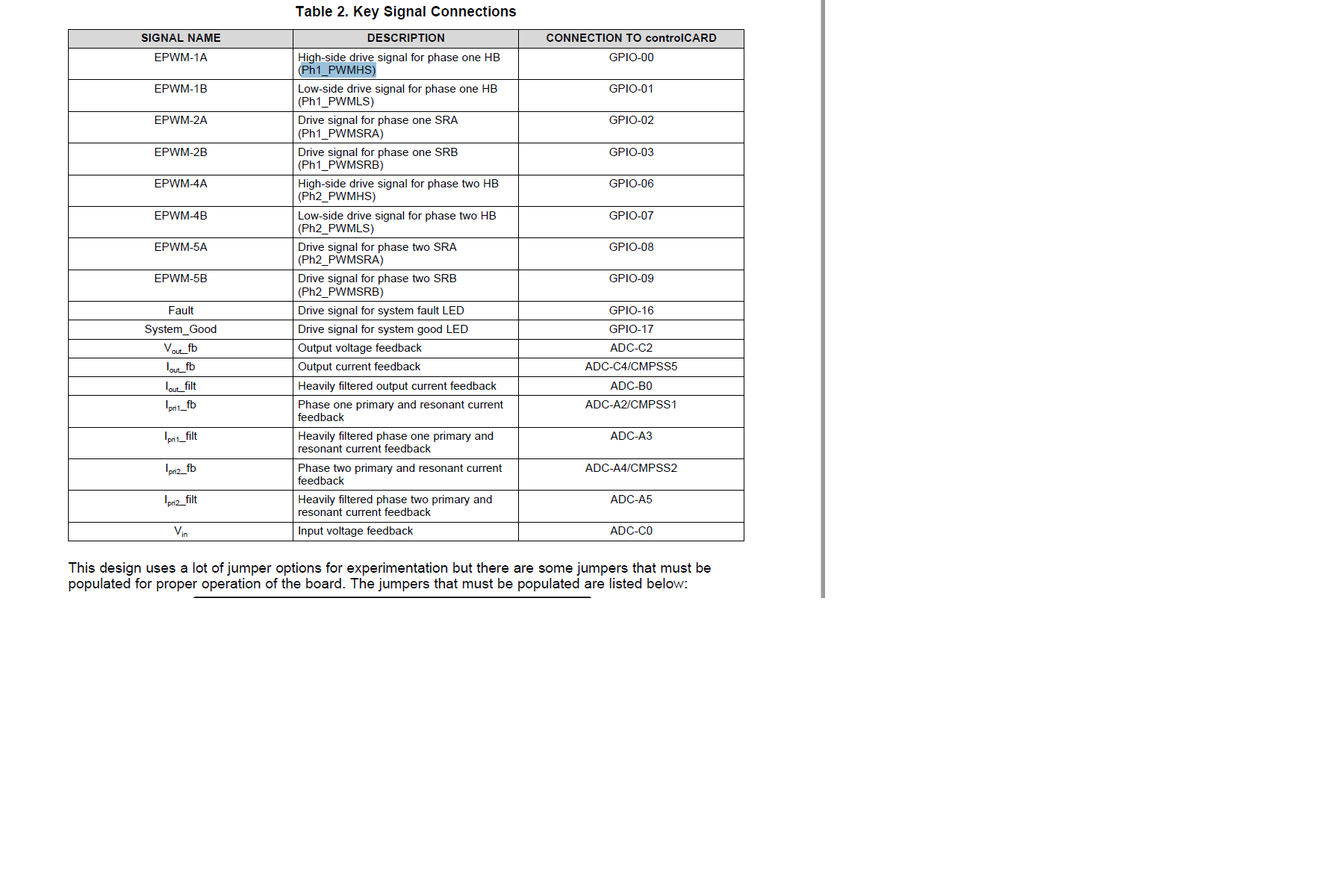

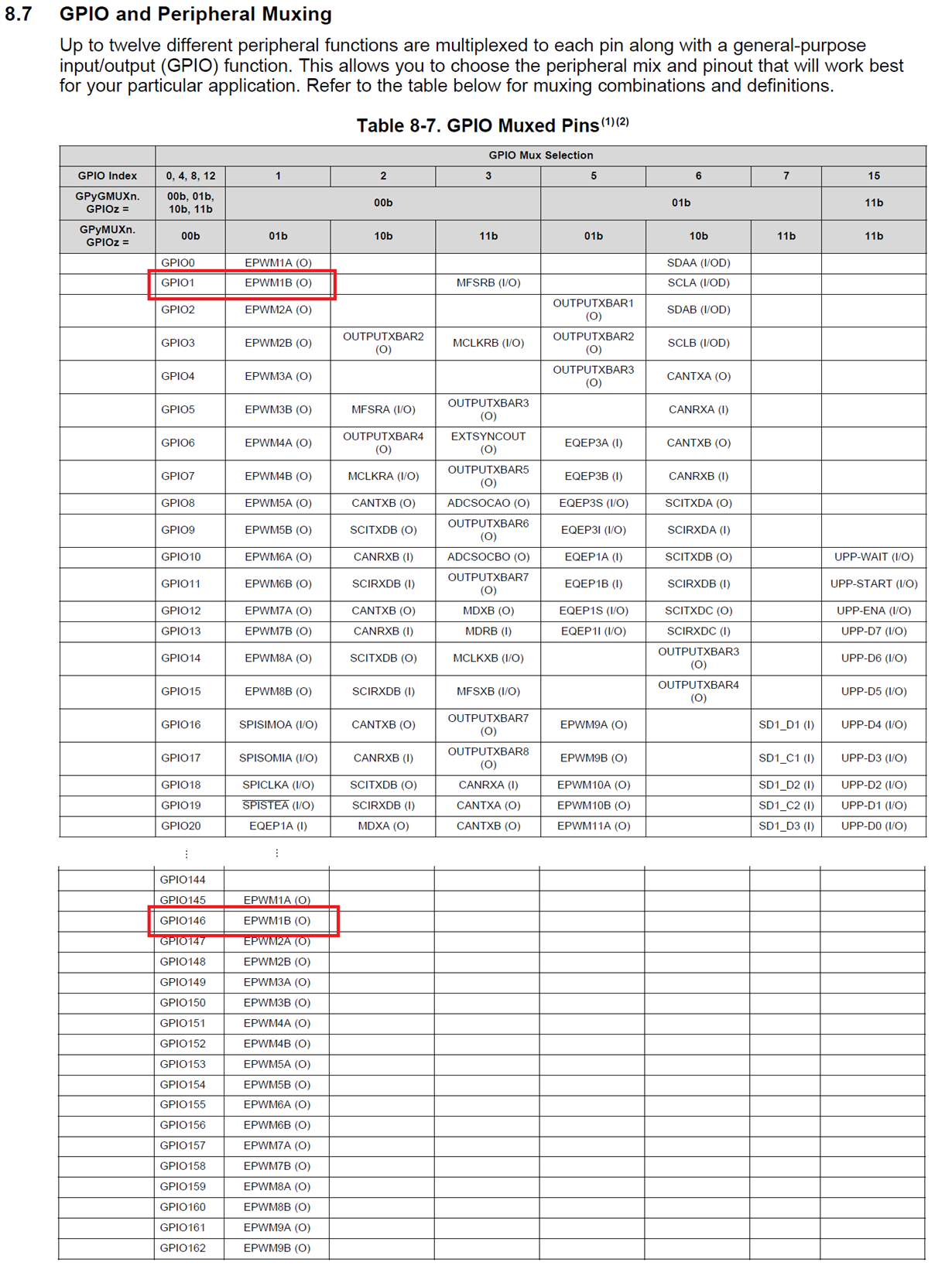

I am working on TIDM 1001. C:\ti\controlSUITE\development_kits\TIDM_1001\v1_00_00_00\f2837x\HV2PHILLLC. I can see the table in the document "TIDUCT9.pdf" location is here C:\ti\controlSUITE\development_kits\TIDM_1001\v1_00_00_00\docs. Table 2. Key Signal connections. It already selected particular GPIO to certain signals. But How can I change it? for that where should I make changes. Is there any tutorial that how to change GPIO in code? I am talking about this table. Also when I observed the code I can't understand how GPIO assigned to particular signal, here as an example I have also shared a screenshot of code related to PWM_LS_PH1, it is not mentioned anywhere that it will connect to GPIO 01. How to understand the selection process of GPIO for particular signal, once I understand this then I can also change it if my application requires.