Hi,

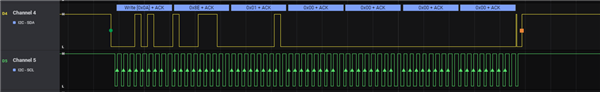

after successful communication with REGISTER_I2C, I have a new big problem: Startup time.

WDTCTL = WDTPW + WDTCNTCL + WDTIS_4; BSP_configureMCU(); __bis_SR_register(GIE);

This code is not working while function BSP_cofigureMCU() needs over 1 second (!) to finish.

WDTCTL = WDTPW + WDTCNTCL + WDTIS_3; BSP_configureMCU(); __bis_SR_register(GIE);

This works fine because WDT reset time is set to 16 seconds.

I need a Startup time below 200 ms and here is the question is this theoretically possible?

Best regards

Igor