Other Parts Discussed in Thread: UNIFLASH

Tool/software:

hello

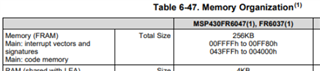

We are working on a project to develop a water meter with msp430fr6047.

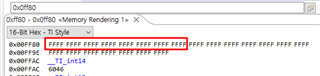

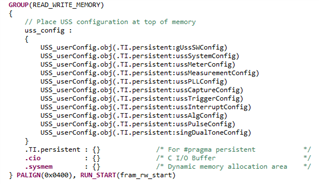

I'm trying to use SPI flash (w25q40) to input user-defined variables.

The code used for development is UltrasonicWaterFR604x_02_40_00_00. Are there any examples or references that match the code?

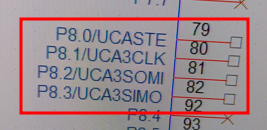

The spi flash connection port is as follows.

I need help.

thank you