Tool/software:

Hi All,

[Currently occurring problems]

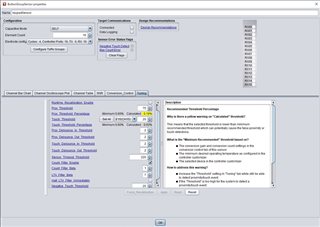

1, The sensitivity of the sensor sometimes deteriorates without any particular action being taken.

→The frequency of occurrence is 1 to 2 weeks after the power is turned on for several models.

2, The problem occurs only with sensors that are frequently touched.

3, Once the sensor sensitivity becomes bad, it cannot be recovered unless it is forcibly shut down.

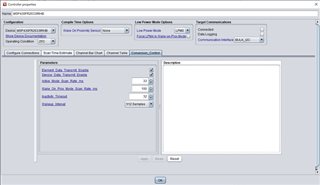

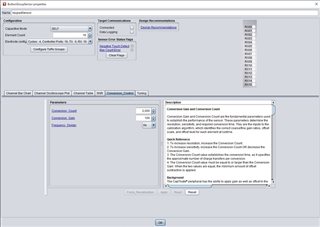

4, Conversion Count = 1000, Runtime Recalibration = Disable

5, The electrode is made of an acrylic plate glued on top of a sheet.

Please let me know how to improve it.

Best Regards,

Ito