Tool/software:

I'm trying to sort out the DCO-FLL configuration/calibration. I read through UG, datasheet and MSP430FR2xx/FR4xx DCO+FLL Applications Guide.

I still don't have all of it straight. Please indicate below where I'm right and where I'm wrong. That will help me make it through!

From User's Guide:

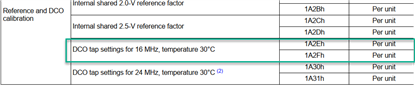

I assume the values below (from datasheet) map right into CSCTL0 register. 16-bit for 16-bit, that would fit. Right?

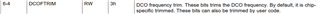

However, according to DCOFTRIM bits description, they also play a role in the overall DCO calibration. Right?

"Chip-specific trimmed", does that mean "each individual die"? If so, I would expect these bits to be recorded in the Device Descriptor. Are they part of 0x1A2E-0x1A30 or elsewhere or not accessible and automatically applied when DCOFTRIMEN=0?

One way or the other, I assume the tap settings from the Dev Desc is valid ONLY with default DCOFTRIM value or with DCOFTRIMEN=0...

Regards