Tool/software:

《MSP430FR58xx, MSP430FR59xx, and MSP430FR6xx Family User's Guide》21.2.5 Multi Tone Generation described:

Finally setting SAPH_AXPGCTL.XMOD = 2 to terminates the multi tone. The last regular excitation pulses

are followed by stop pulses. Then PPG_A goes to Pause phase again (see Figure 21-10 and Figure 21-9).

The stop pulses have a 180° phase shift compared to the last regular excitation pulses. The stop pulses

have same frequency as the last regular excitation pulses。

to my understanding,stop pulses has two important attributes:180° phase shift and same frequency, compared to the last regular excitation pulses 。

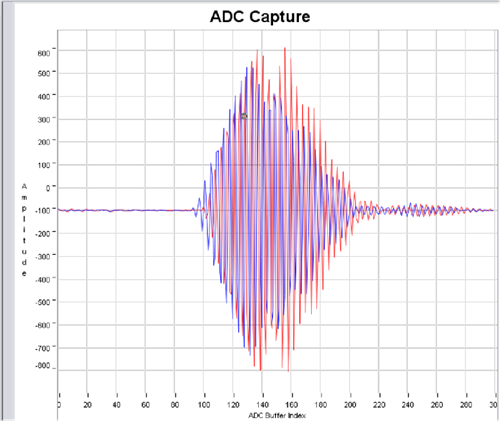

This also conforms to the accompanying diagram in the document:

(Figure 21-11. PPG_A Multi Tone Generation With SAPHPGC.PPOL = 1(Starts With Low Polarity))

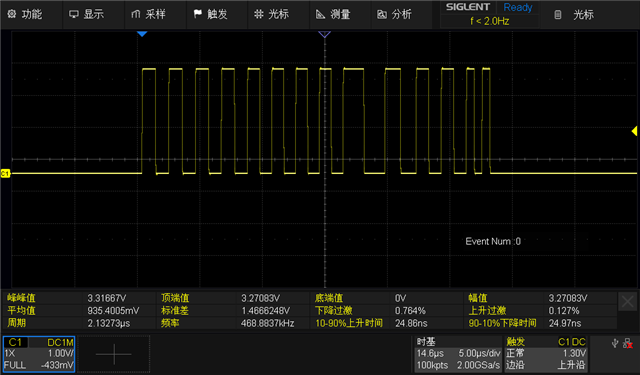

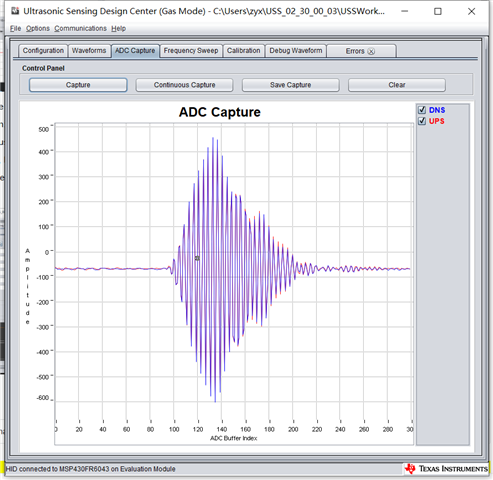

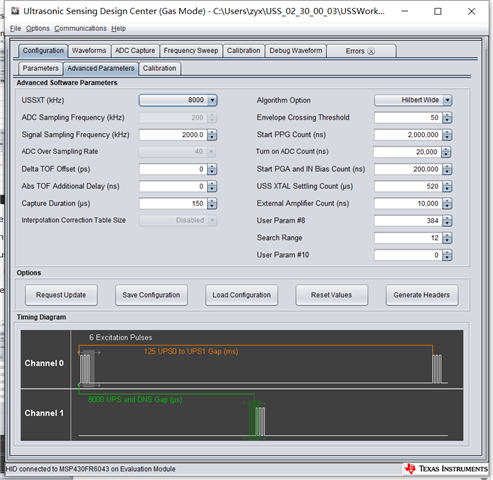

However, in the example routines provided on the official website, the frequency of the "stop pulses" section is pre-defined. This configuration refers to the following preset settings, which do not conform to the documentation instructions:

const USS_App_AddlTXSequence_t addtlTXSeqs[USS_APP_ADDTL_TX_SEQUENCES_MAX] =

{

// Sequence # 1

// 2 trill pulses

// X-Pulse #1 = 1 @300kHz (with 80Mhz PLL)

// E-Pulse #1 = 1 @400kHz (with 80Mhz PLL)

// X-Pulse #2 = 2 @500kHz (with 80Mhz PLL)

// E-Pulse #2 = 2 @500kHz (with 80Mhz PLL)

{

.numTrillCycles = 2,

.xpulse = {1,2},

.xhper = {133,80},

.xlper = {133,80},

.epulse = {1,2},

.ehper = {100,80},

.elper = {100,80},

.binPatternLen = 14,

.binPattern = {1,1,-1,-1,1,-1,1,-1,1,-1,1,-1,1,-1}

},

// Sequence # 2

// 2 trill pulses

// X-Pulse #1 = 1 @300kHz (with 80Mhz PLL)

// E-Pulse #1 = 1 @400kHz (with 80Mhz PLL)

// X-Pulse #2 = 2 @500kHz (with 80Mhz PLL)

// E-Pulse #2 = 2 @800kHz (with 80Mhz PLL)

{

.numTrillCycles = 2,

.xpulse = {1,2},

.xhper = {133,80},

.xlper = {133,80},

.epulse = {1,2},

.ehper = {100,50},

.elper = {100,50},

.binPatternLen = 25,

.binPattern = {1,1,1,1,-1,-1,-1,1,1,1,-1,-1,1,1,-1,-1,1,1,-1,-1,1,-1,-1,1,-1}

}

};

I would like to confirm whether the code in this part needs to be adjusted by the manufacturer based on the actual working frequency of the product?

.

.