How to start.. Whatever. Let's talk about this.

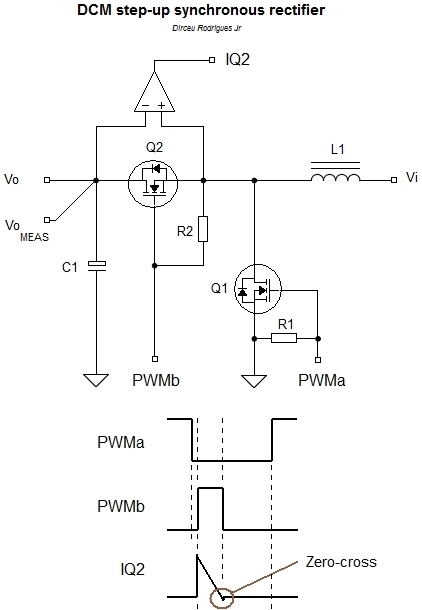

There's around microcontrollers with boost converters built-in which allows to boost power supply voltage from 0.7V to (3V) operating VCC of uC. They cost money and they are not msp430 (G-series). Actually question is not about picking right piece of silicon for low voltage application but having fun building useful stuff out of virtually nothing. We can build boost converter using PWM peripheral, MOSFET, inductor and Schottky diode. Energy storage capacitor will be helpful indeed. All what's needed - proper control of PWM to sustain target (3V) voltage all the time. Simple, isn't it?

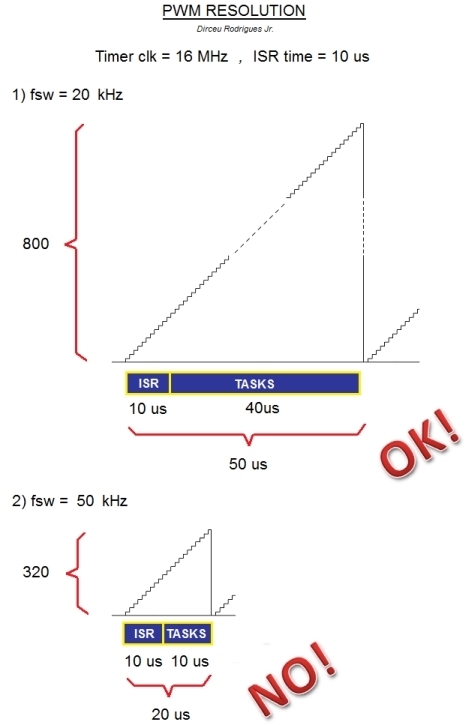

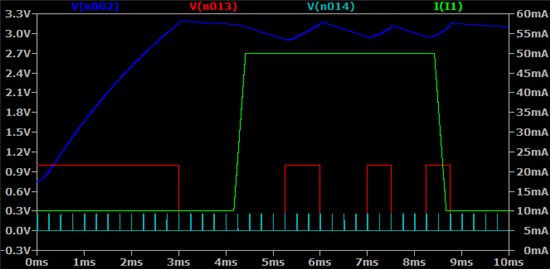

So here's application: we have G-series msp430 (2553?) with boost converter which powers microcontroller from disposable ~3V battery, we need to squeeze all we can get out of it. The closer battery gets to 0V still operating uC at 3V - the better. Allowed VCC range is 2.5-3.3V. Application have ultra low power sleep time when RTC using 32kHz fork oscillator shall be running, then there's "high power" moments when microcontroller shall calculate something, light LED or even sustain power for RF transceiver. For starter let's assume that high power means 20mA at 3V and lasts 10ms, then whatever... 1 or 60 minute low power which shall consume close to nothing. Immediately I see two main problems here: how to measure VCC voltage most energy-efficient way and how to control PWM such a way that we don't overshoot or undershoot target 3V VCC no matter how big or small consumption is. During low power state PWM for sure can be off but we need to wake-up in time to charge capacitor. Otherwise we are dead. Question is - how we determine when to wake-up from low power to start PWM for capacitor recharge? Measure or estimate or both? How? During high power state we need to drive boost converter such a way so VCC voltage does not go outside defined (2.5 - 3.3V) boundaries. This is most challenging part I think.

For sure I have some ideas and considerations which I will share later but I am eager to hear yours first.

p.s. Those who are sceptical, not interested or simply in bad mood - please do not waste electronic ink of The Internet :)