Hi,

I am using an external temperature probe (MCP9700-E/TO) and msp430g2553

And this code

void checktemp(void)

{

ADC10CTL0 &= ~ENC; // Disable ADC

ADC10CTL0 = SREF_0 +SREF_1 + ADC10SHT_3 + REFON + ADC10ON + ADC10IE; //+REF2_5V// Use reference, 1v5 (2v5 disabled)

// 16 clock ticks, internal reference on

// ADC On, enable ADC interrupt, Internal = 'ref'

ADC10CTL1 = ADC10SSEL_3 + INCH_6; // Set chan6, SMCLK

__delay_cycles (30); // Delay to allow Ref to settle, was 20

ADC10CTL0 |= ENC + ADC10SC; //enable and start conversion

temp=(ADC10MEM);

}

The code is over sampled 12 time per reading and is pretty stable with temperauture increasing/decreasing/remaining constant. The probe also has decoupling caps on.

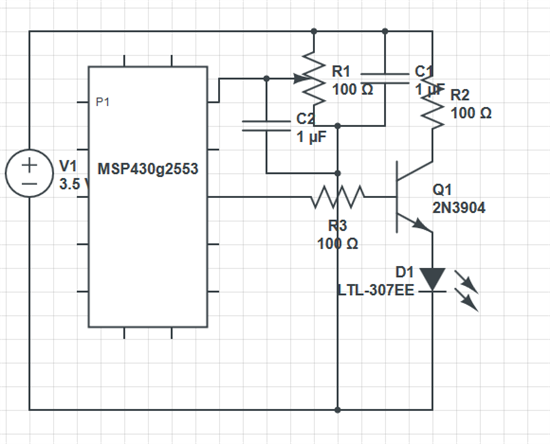

The problem comes when I switch an external heating element on/off with the msp430. This is through a transistor, another transistor then an ssr.

Turning the output off causes the adc to decrease about 10 units, even with the over sampling. This causes the output to oscillate on/off/on etc and also the temperature readout to fluctuate somewhat wildly.

Am I doing something wrong or is the internal reference going to be that unstable during switching?