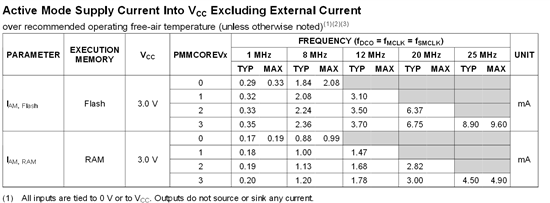

-MSP430F5419A datasheet(http://www.ti.com/lit/ds/symlink/msp430f5419a.pdf) provides typical power consumption as 230uA/Mhz and on page 42 it shows max value as 960uA/Mhz @ 25Mhz

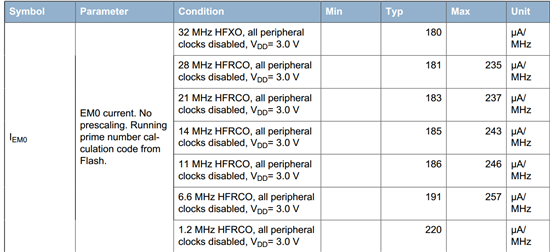

-EFM32G222 (http://www.silabs.com/Support%20Documents/TechnicalDocs/EFM32G222.pdf) which has ARM cortex M3, shows power consumption as 180µA/ MHz and on page 10 it shows current consumption as 235µA/ MHz @ 28Mhz

since ARM is 32 bit ,does it mean that EFM32G222 is low power compared to many of MSP430 series MCU's ?

-Both MCU's show thes stats @3.0V only and @ Run or Active mode and code executed from Flash. so,Is my comparision fair or am I totally wrong, Please correct me?

Thank You.