Hi Everybody,

I had a lot of problem until I found the cause, it take me a long time to trace it down.

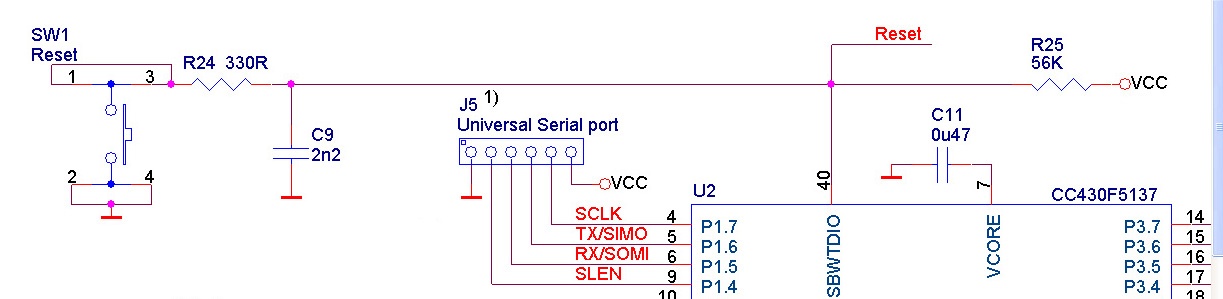

It's the floating input TEST pin.

It is recommended to left the TEST pin unconnected. But the TEST pin is need in the factory to program the MSP430 with the Spy-Bi-Wire.

This TEST pin is very sensitive and picks up EMI very easy and the MSP430 behaves erratic, like resetting itself.

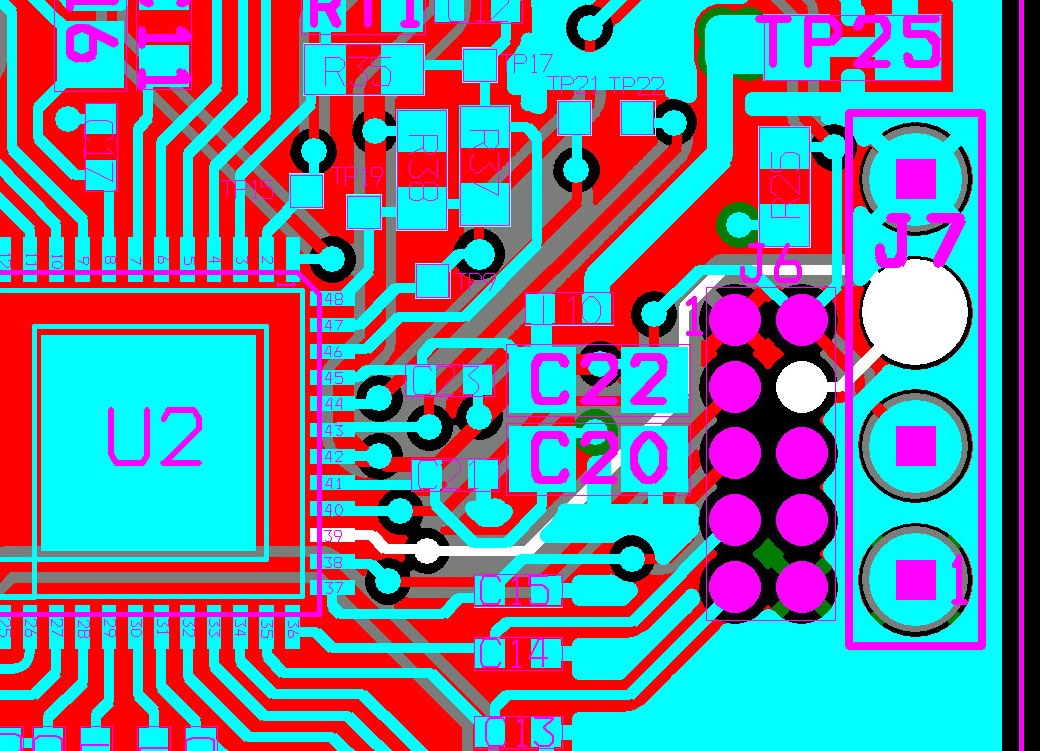

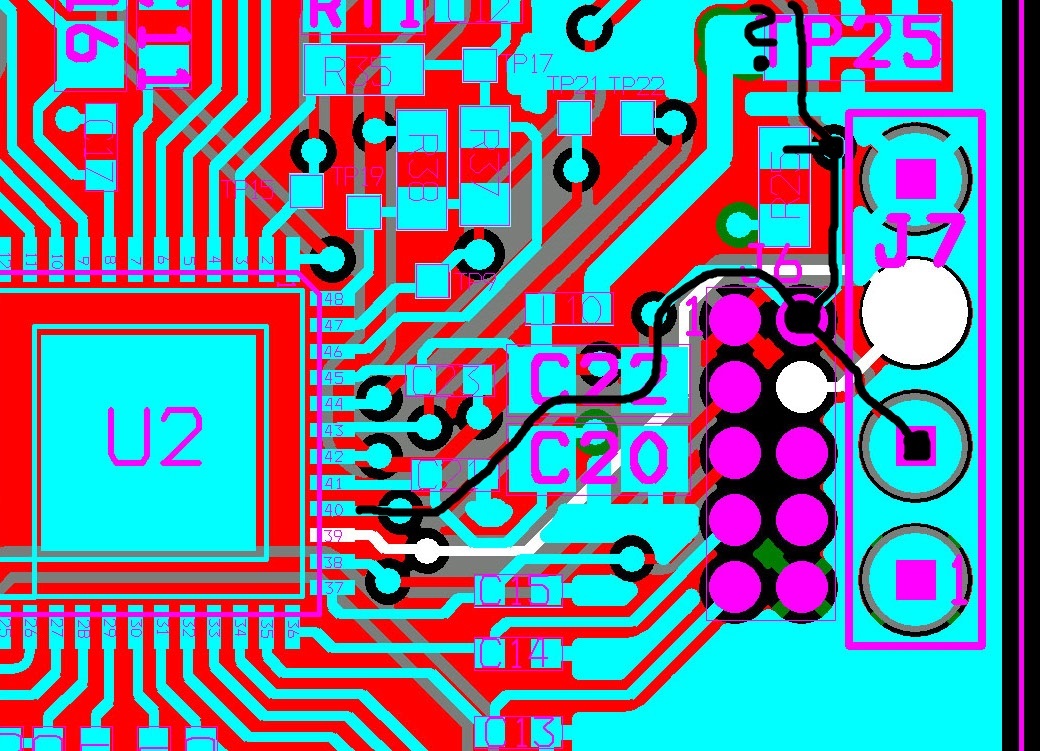

I came up with a solution the solves the EMI problem and still be able to run the Spy-Bi-Wire correctly. Infact the Spy-Bi-Wire works as well better with this configuration.

In the end of the trace I have add a 1k resistor to ground and a 1nF capacitor to ground.

Now to my questions:

1. It is recommended to left the TEST pin unconnected. Why?

2. Seems the TEST pin is a input, I can as well short it to ground and that solves the EMI problem too. Is there any problem with that?

I appreciate any comment on my solution and questions?

Regards,

Rene