Other Parts Discussed in Thread: MSP430WARE

I used MSP430L092 example code for measuring temperature sensor value but It seems that there is a delay for operation. For example; I set a condition that if DegC is greater than 30, P1.4 port that is tied LED is high. After 42 seconds, my LEDis high. I don't understand this delay. Respectively, If I set greater than 20 this sensor result, it is high later 30 seconds. I put below example code that I rearranged.

/* --COPYRIGHT--,BSD_EX

* Copyright (c) 2012, Texas Instruments Incorporated

* All rights reserved.

*

* Redistribution and use in source and binary forms, with or without

* modification, are permitted provided that the following conditions

* are met:

*

* * Redistributions of source code must retain the above copyright

* notice, this list of conditions and the following disclaimer.

*

* * Redistributions in binary form must reproduce the above copyright

* notice, this list of conditions and the following disclaimer in the

* documentation and/or other materials provided with the distribution.

*

* * Neither the name of Texas Instruments Incorporated nor the names of

* its contributors may be used to endorse or promote products derived

* from this software without specific prior written permission.

*

* THIS SOFTWARE IS PROVIDED BY THE COPYRIGHT HOLDERS AND CONTRIBUTORS "AS IS"

* AND ANY EXPRESS OR IMPLIED WARRANTIES, INCLUDING, BUT NOT LIMITED TO,

* THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

* PURPOSE ARE DISCLAIMED. IN NO EVENT SHALL THE COPYRIGHT OWNER OR

* CONTRIBUTORS BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL, SPECIAL,

* EXEMPLARY, OR CONSEQUENTIAL DAMAGES (INCLUDING, BUT NOT LIMITED TO,

* PROCUREMENT OF SUBSTITUTE GOODS OR SERVICES; LOSS OF USE, DATA, OR PROFITS;

* OR BUSINESS INTERRUPTION) HOWEVER CAUSED AND ON ANY THEORY OF LIABILITY,

* WHETHER IN CONTRACT, STRICT LIABILITY, OR TORT (INCLUDING NEGLIGENCE OR

* OTHERWISE) ARISING IN ANY WAY OUT OF THE USE OF THIS SOFTWARE,

* EVEN IF ADVISED OF THE POSSIBILITY OF SUCH DAMAGE.

*

*******************************************************************************

*

* MSP430 CODE EXAMPLE DISCLAIMER

*

* MSP430 code examples are self-contained low-level programs that typically

* demonstrate a single peripheral function or device feature in a highly

* concise manner. For this the code may rely on the device's power-on default

* register values and settings such as the clock configuration and care must

* be taken when combining code from several examples to avoid potential side

* effects. Also see www.ti.com/grace for a GUI- and www.ti.com/msp430ware

* for an API functional library-approach to peripheral configuration.

*

* --/COPYRIGHT--*/

/* Description: ADC Temperature Sample */

/****************************A_POOL ADC Conversion *******************************/

/* */

/* */

/* +----L092---+ */

/* |*1 14 | */

/* | 2 13 | */

/* | 3 12 | */

/* | 4 11 | */

/* | 5 10 | */

/* | 6 9 | */

/* | 7 8 | */

/* +-----------+ */

/* */

/* D.Dang/ D.Archbold/ D.Szmulewicz /F. Chen */

/* Texas Instruments Inc. */

/* Built with IAR Version 5.51.1 and CCS Verison 5.3.00090 */

/*********************************************************************************/

#include <msp430.h>

int Result;

volatile short int DegC;

int main(void)

{

WDTCTL = WDTPW + WDTHOLD; // Stop WDT

// Begin Configuration of the A-POOL registers

APCTL = 0; // Clear APCTL register

APIE |= EOCIE; // Enable Interrupt for End of Conversion

APTRIM = REFTSEL;

APVDIV = TMPSEN; // Enable Temperature Sensor

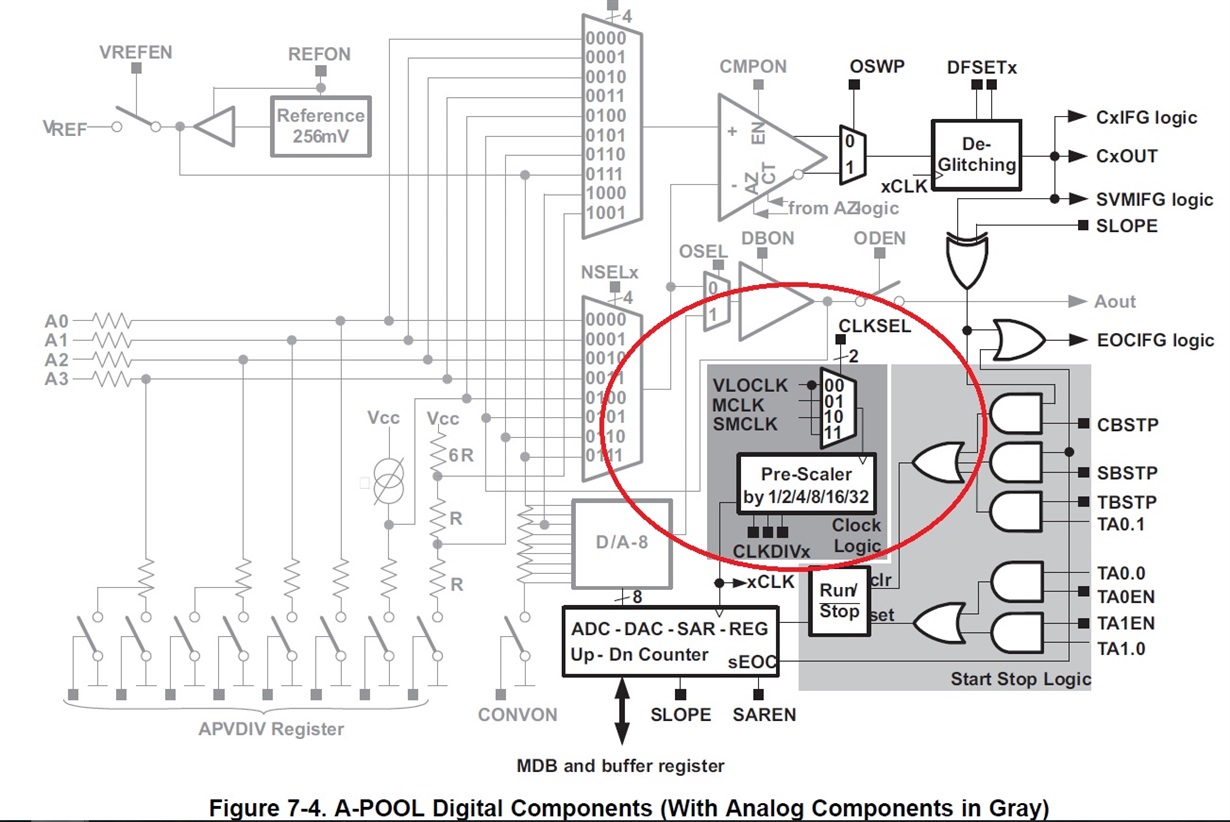

APCNF = CMPON+DBON+CONVON+APREFON+CLKSEL_MCLK; // Configure A-POOL elements, Select MCLK as A-POOL Clock Source

P1DIR |= (BIT4+BIT5+BIT6);

while(1)

{

APCTL = OSEL+ODEN+OSWP+APPSEL_4+APNSEL_5; // Set Channels and Start Conversion--+ODEN+

APINT = 0x00; // Clear ADC-DAC-REG

APIFG = 0;

APCTL |= CBSTP+SBSTP+RUNSTOP;

__bis_SR_register(LPM0_bits + GIE); // Enter LPM0 w/ interrupts enabled

Result = APINT;

DegC =(((Result-179)*125)/58) + 30; // Refer to datasheet for accuracy and offset specs

if(DegC>20){

P1OUT|=BIT4;

}

else{

P1OUT&=~BIT4;

}

__no_operation(); // SET BREAKPOINT HERE

}

}

//A_POOL Interrupt Service Routine

#if defined(__TI_COMPILER_VERSION__) || defined(__IAR_SYSTEMS_ICC__)

#pragma vector=APOOL_VECTOR

__interrupt void A_POOL(void)

#elif defined(__GNUC__)

void __attribute__ ((interrupt(APOOL_VECTOR))) A_POOL (void)

#else

#error Compiler not supported!

#endif

{

APIFG = 0; // Clear Interrupt Flag

__bic_SR_register_on_exit(LPM0_bits); // Exit Active to calculate Temperature

}

Please, Can someone give me an advice prevent this delay?

Thanks in advance