Other Parts Discussed in Thread: MSP430F5659, MSP430FR6989, MSP-GANG,

hi

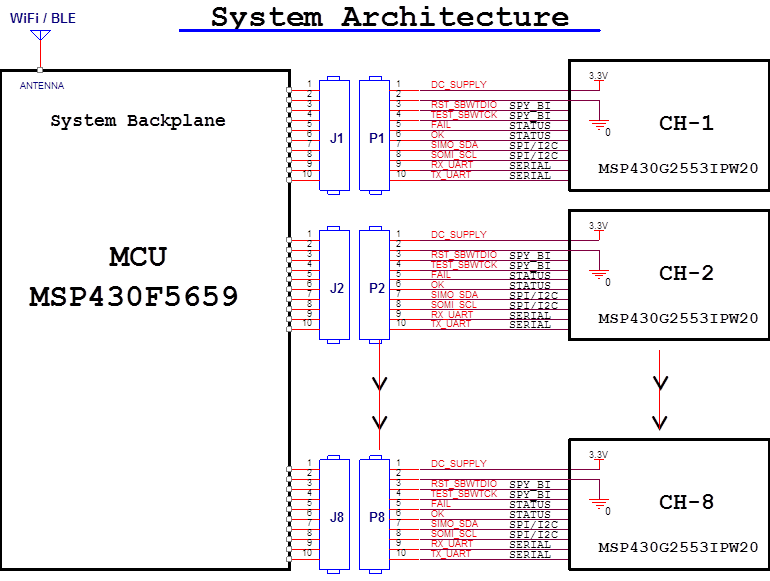

in our project We will have one backplane contains MSP430F5659 MCU that should communicate and program 8 channels containing MSP430G2553IPW20 MCU’s,

This backplane will have TI’s selected WiFi/BLE solution & USB as well.

In order to proper design the hardware infrastructure, we must know if there is a simple way using the BSL to run and program each one of the 8 channels in sequence.

That will be uses for future firmware upgrades via WiFi and/or BLE and/or USB (upon user needs).

Looking at attached scheme my infrastructure able to use I2C , TX/RX (uart) and SBW as well.

we would like to know:

- What is the best recommended method to do it ? (I2C , TX/RX or SBW ?).

- Do you have any sample code ?

- Any additional information/recommendation ?