Other Parts Discussed in Thread: CC1310, CSD23285F5, CSD23280F3, TIDA-01228

i am working on the tidud25a.pdf

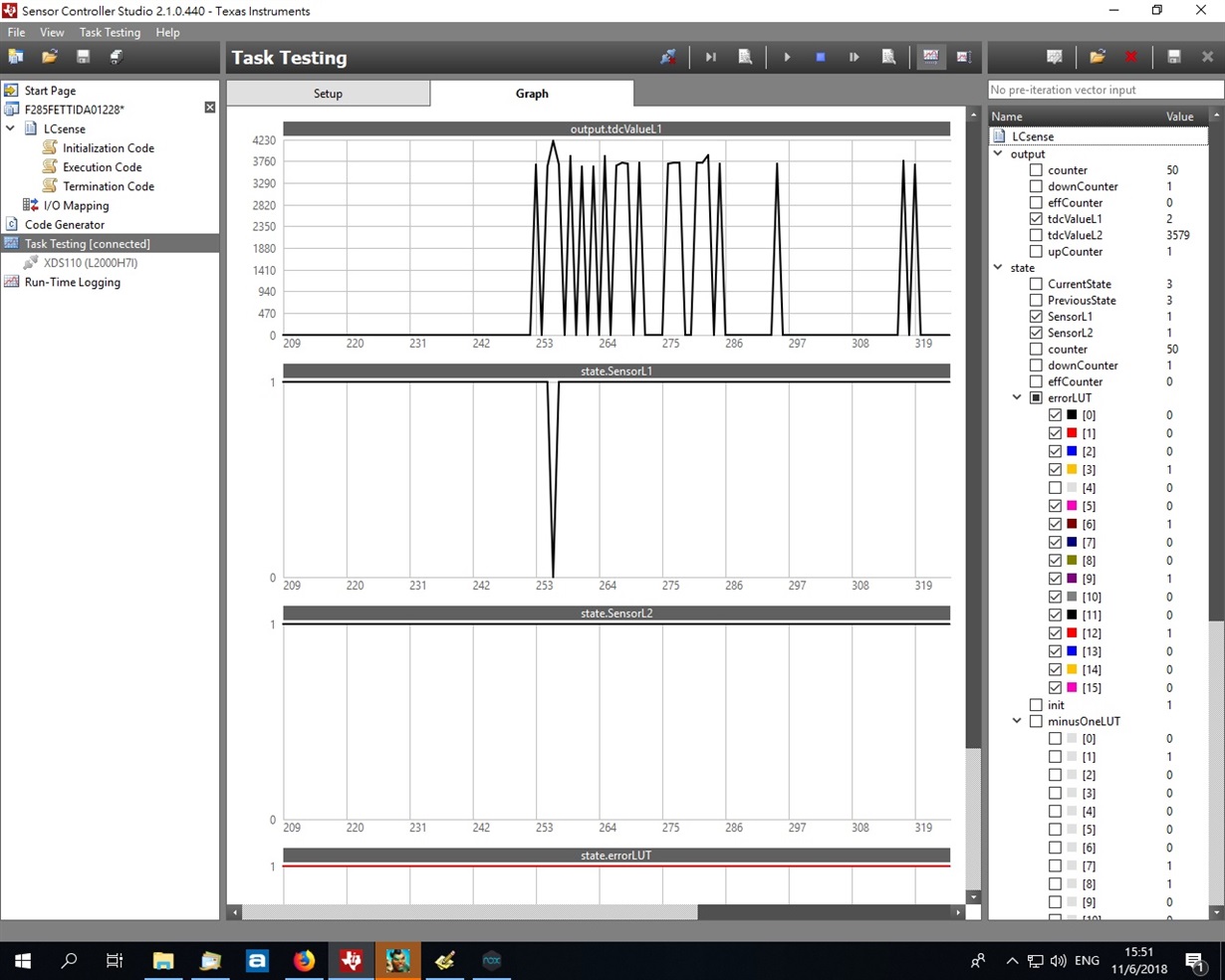

In page 12, the diagram show the waveform of the output and trigger point

however , i try to make the same circuit

the waveform is completely different from it~

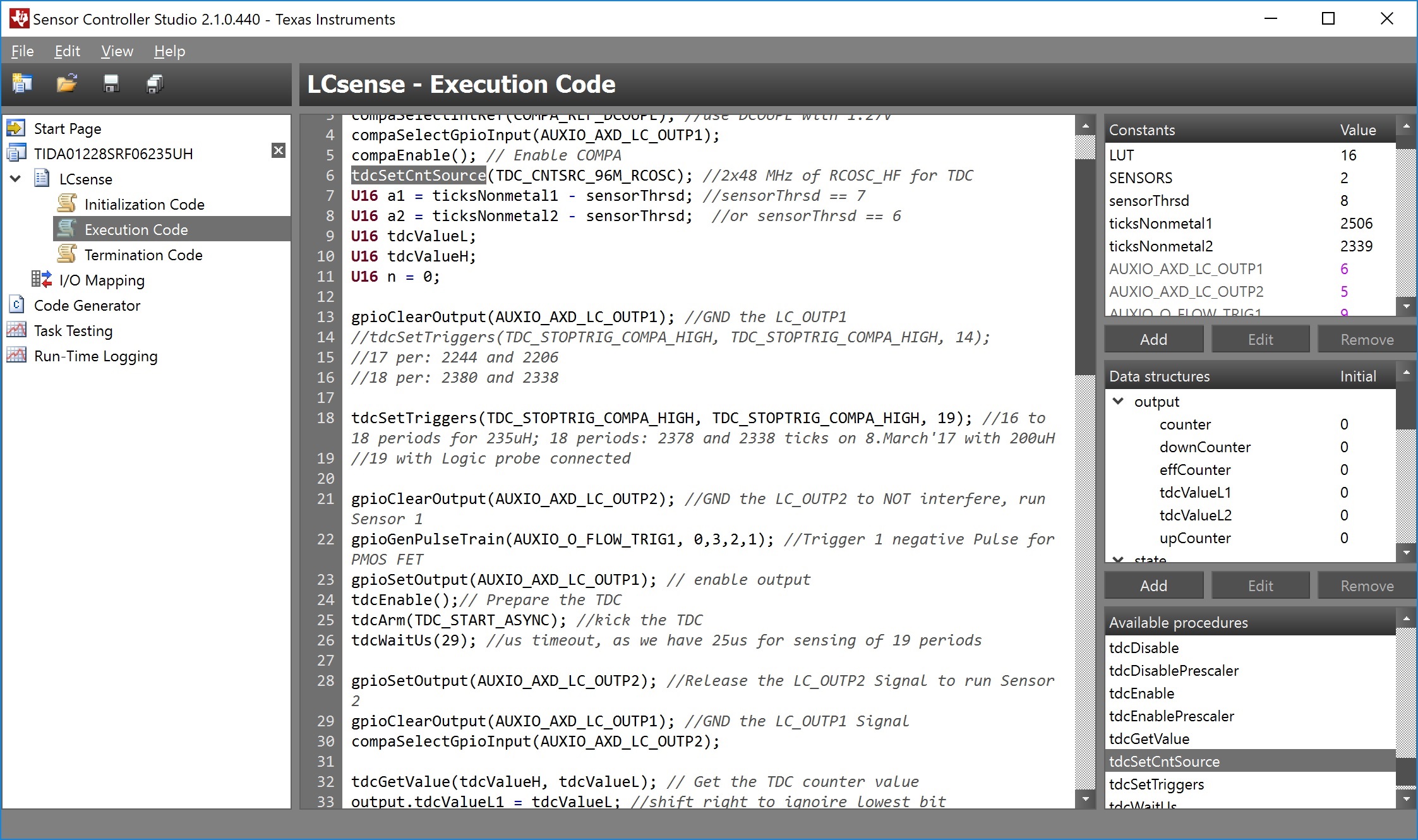

for software , i run the attached .scp file in the cc1310 launchpad

here is the attachement for my taping point

the scope 1 is the output of the LC

while scope 2 is the trigger point

thanks if any help or suggestion~

thanks~

Jeff