Hello I have ADC problem,

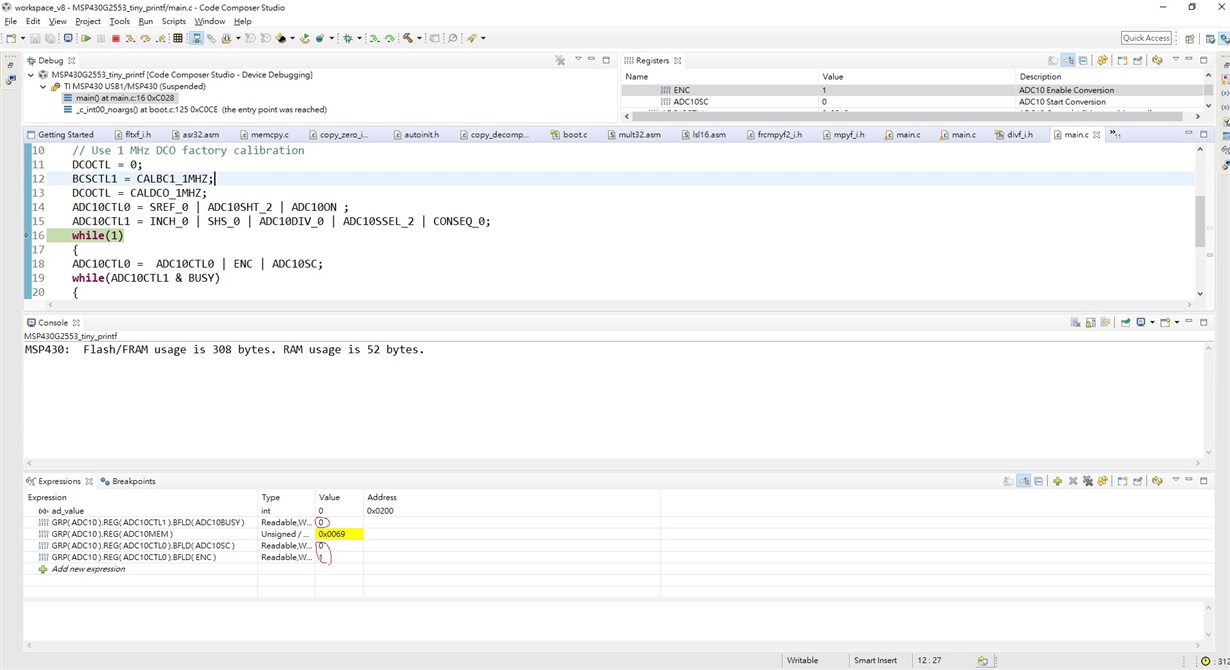

code

-----

int adc_value;

void main(void)

{

WDTCTL = WDTPW + WDTHOLD;

ADC10CTL0 = SREF_0 | ADC10SHT_2 | ADC10ON ;

ADC10CTL1 = INCH_0 | SHS_0 | ADC10DIV_0 | ADC10SSEL_2 | CONSEQ_0;

while(1)

{

ADC10CTL0 = ADC10CTL0 | ENC | ADC10SC;

while(ADC10CTL1 & BUSY)

{

ad_value=ADC10MEM;

ADC10CTL0 &= ENC;

}

}

}

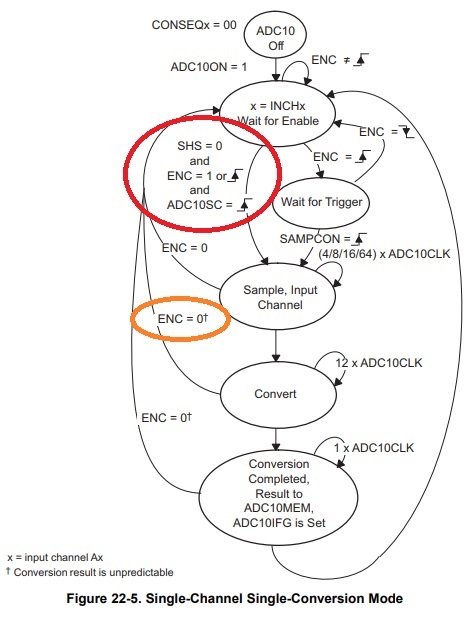

I have see datasheet of MSP430G2553 and set CONSEQ at 00 mode

and see process picture;

I sure that SHS=0,ENC=1,ADCSC=1;but in debug i always see SHS=0,ENC=1,ADC10SC=0 BUSY=0;

and it should goto convert process and busy should change to 1; but ADC10SC & BUSY always =0 ;why??

and it change convert.....at adc10MEM get value; it should get busy for 1 at convert; and complete busy sholud auto goto zero, but it doesn't

please see video ;

how to explain ; i want my code enter to "while(ADC10CTL1 & BUSY)" loop