Part Number: MSP430F5324

Other Parts Discussed in Thread: UNIFLASH

Hi Sir,

As below are my request, please kindly to reply.

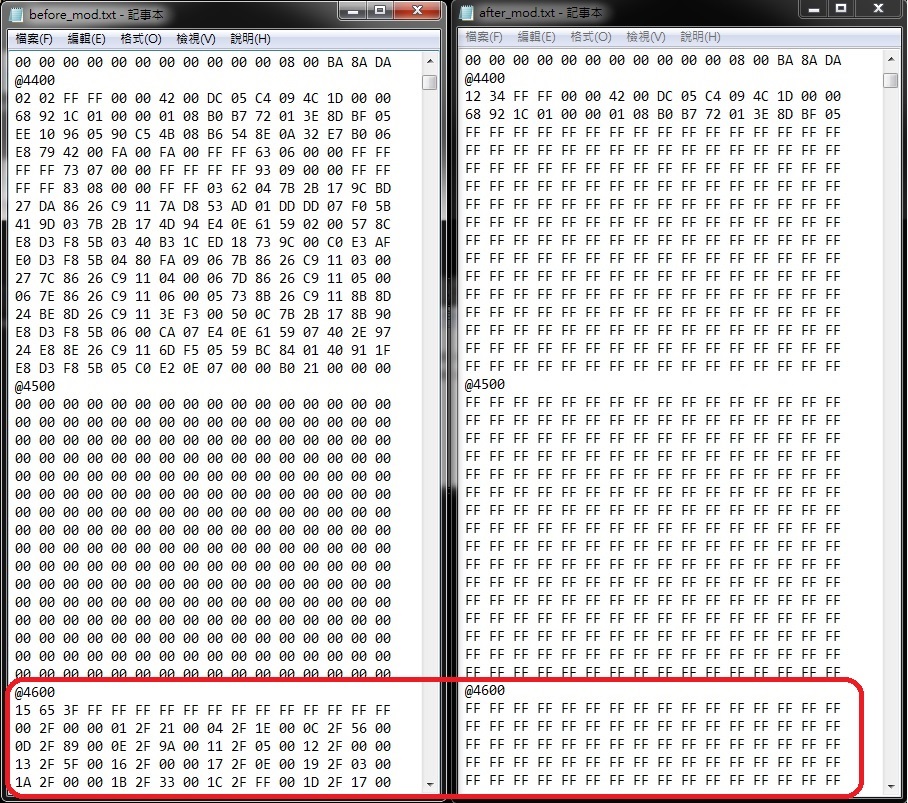

1.First, we programmer main code to MSP430

2. 2nd, We would to direct write data to memory range [4400h-45FFh] and can't destroy main code.

3. This is for factory MP. so, we would to use CLI to re-package to GUI for operator work.

SO, CLI can be completed write direct memory address??would you have any example??

BR,

Neal Huang.