hi all...

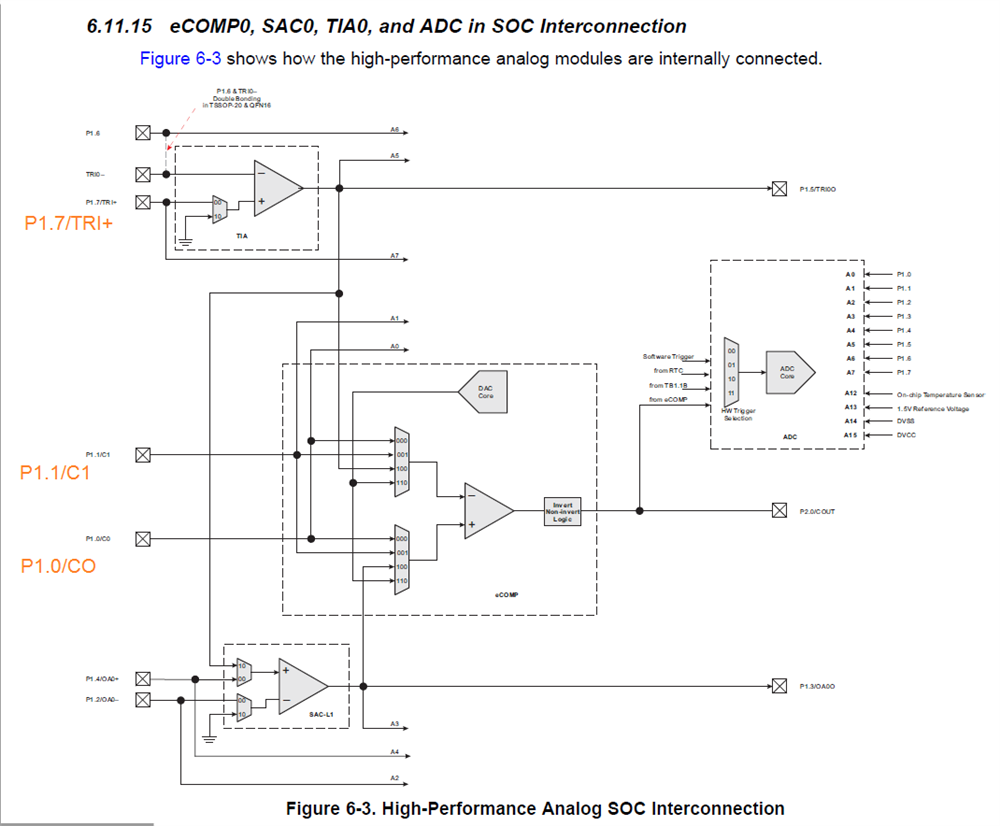

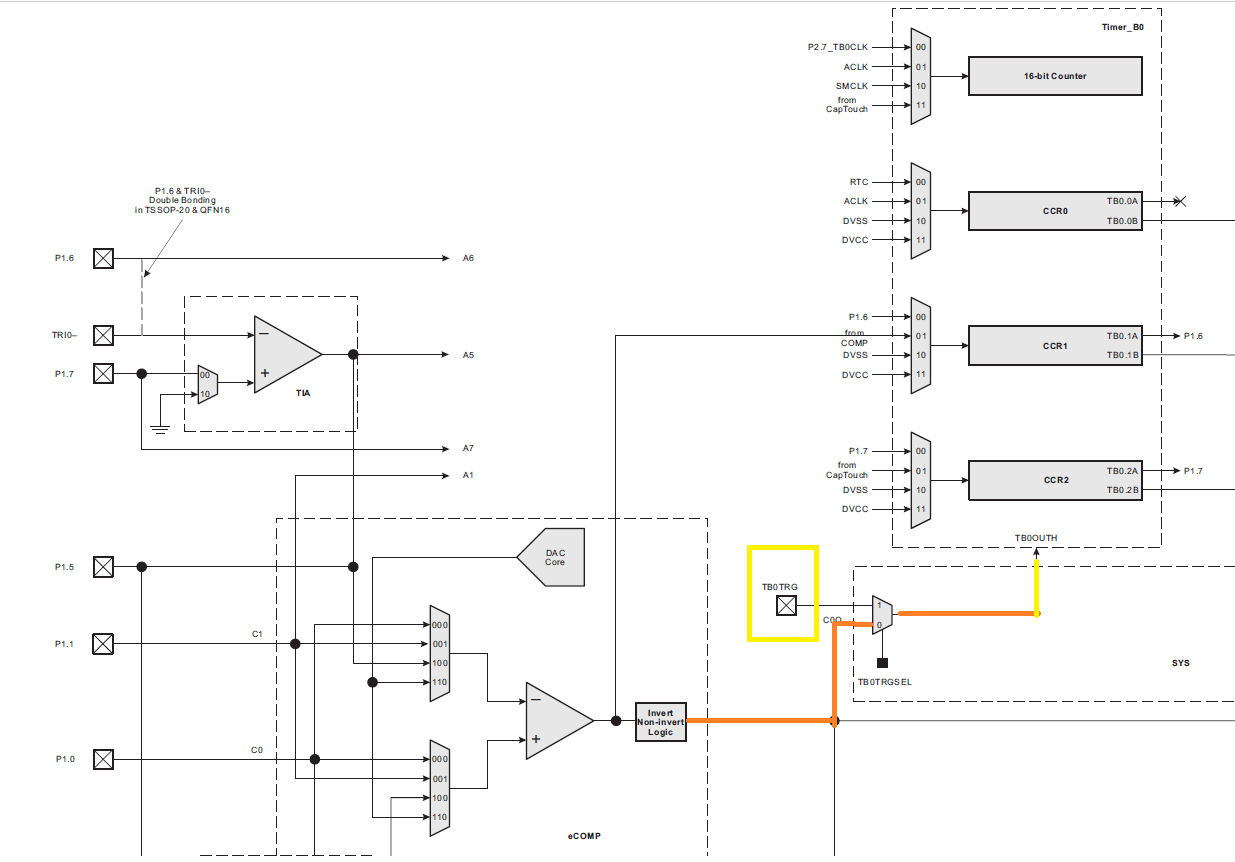

I am working with MSP430FR2311 , VCC is 3.3V.

i am using Timer B0.2 as PWM and use P1.7 for PWM output.

So far everything works fine and I can control PWM.

Something very strange that I never saw,..... When I use P1.1 high on the seam time while PWM working

the voltage of P1.7 PWM output falls from 3.3V to 1V.

It looks like someone is loading but I do not understand what...

I'm also a hardware man and I still can not understand what's going on here...

please help...

Aharon.