Hello

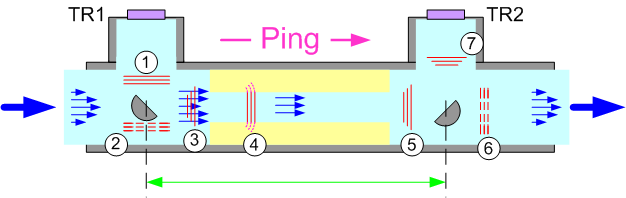

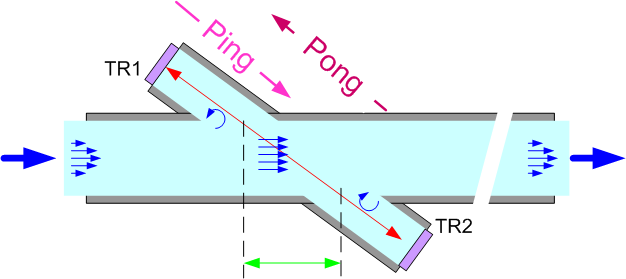

For our product we need to calculate and output the velocity of the fluid in the pipe and the volume accordingly

The product should be generic for multiple pipes diameter sizes and wall thickness, so we plan to calculate the volume afterwards, according to the pipe selected.

The algorithm yield the following results: deltaTOF, totalTOF_UPS and .totalTOF_DNS

Assuming the medium is water and the temperature is 25 degrees Celsius (1480 m/s) and the pipe diameter is 25 DN (33.7 mm)

The question is:

What is the best way to calculate the medium velocity? and volume afterwards.

Real world numbers as an example to the equation can really assist here

Thanks