Other Parts Discussed in Thread: MSP430FR2512, EVM430-CAPMINI

Hello Team,

I will use MSP430FR2512 ic for the Capsense Liquid tolerance design. below is Query

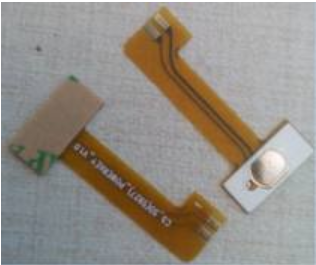

---- I have planned to use mutual capacitance technology, so, I have two electrodes (TX and RX) traces separate in PAD design.

1) Can I place an LED inside the Capsense pad in mutual mode?

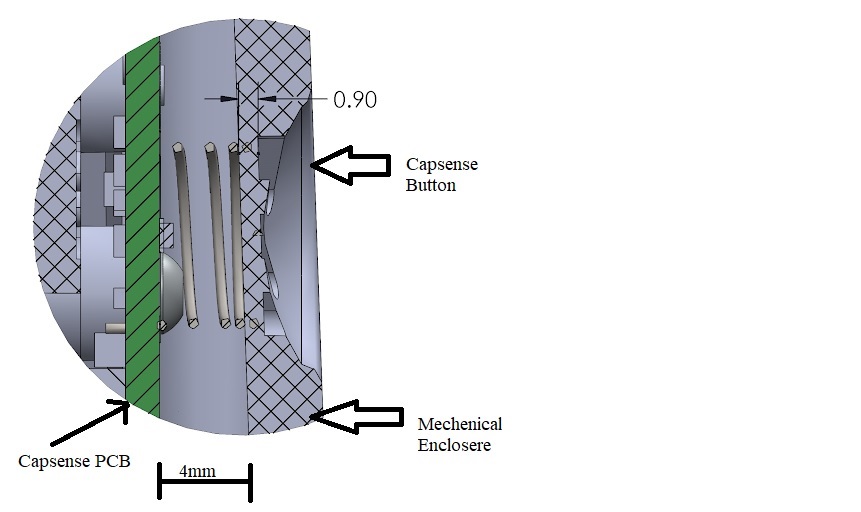

2) In our enclosure Capsense PCB and overlay distance are 4mm. so we will connect both using spring soldered in the cap sense pad. Can I use separate spring for TX and RX electrode?

Please reply ASAP.