Hello,

Currently I am working on a project using the MSP430FR2676 microcontroller with the CapTIvate peripheral. I started designing by using the TI Captivate Design Center, generate the source code, and by starting tuning the variables. One of the variables that is adjustable and has a great impact on the sample rate is the Active Mode Scan Rate and I managed to get the sample rate to 1ms (1KHz).

However, this sample rate is not sufficient for our solution in the product and therefore we would like to increase the sample rate to approximately 8-10kHz. After investigating the Technology Guide and using formulas at the page: Optimizing for the shortest measurement time. it seems to be feasible.

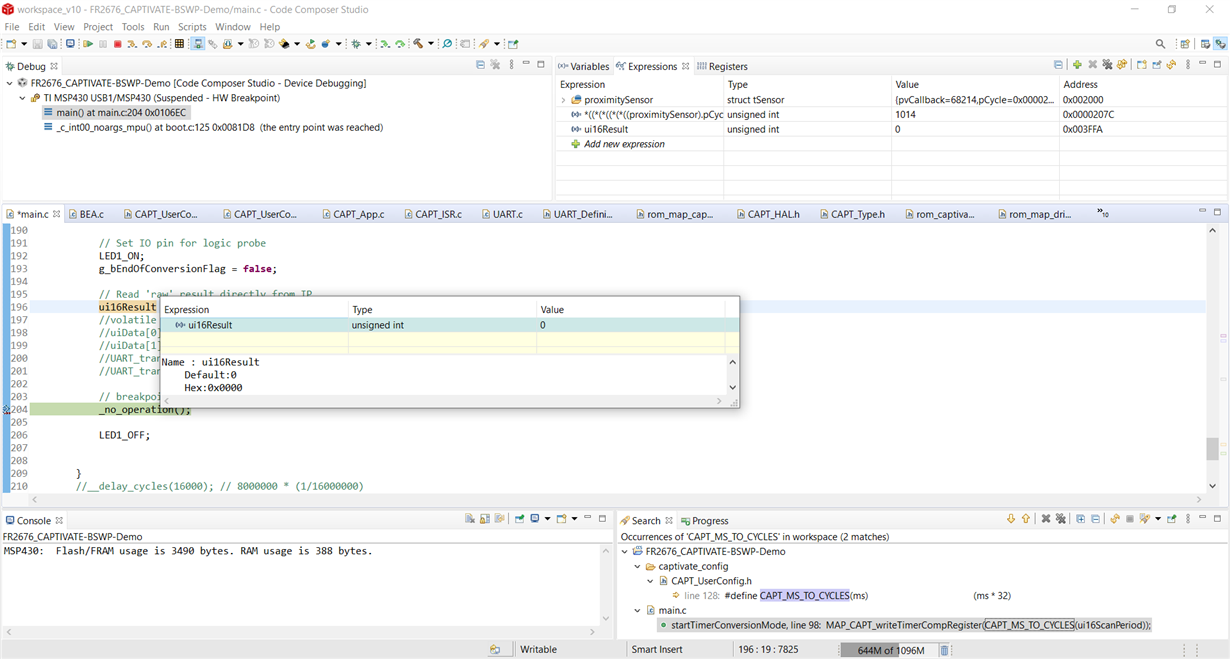

After investigating the generated code, increasing the MCLK to 16MHz, registering a new callback, we found out that a lower level call to the ROM code “CAPT_updateSensor” and “CAPT_updateSensorRawCount” takes approximately 0.5-0.6ms. The self created callback that was registered is fast as expected (1us). By using the “CAPT_updateSensor” method as time reference it can be determined that (1/0.0005)=2000Hz=2kHz can be the maximum sample rate of this solution.

Based on the information above I am not sure on how to improve the sample rate. On the TI Captivate Technology Guide there is a lot of information on how to optimize this peripheral for power consumption. Is there more information on how to optimize the sample rate of this peripheral? Or are there any TI examples available with higher sample rates? Or does anybody have experiences with this?