Hello,

I am developing a demonstrator for a lift application, featuring five EK-TM4C123GXL Boards. I've been trying to get CAN-Bus communication running or a week now, without success. My receiver only reads zeros from the CAN-Bus.

I'll try and give more detail on my setup:

For a start, I wanted to try out the simple_tx and simple_rx examples privided with TivaWare, using two evaluation boards EK-TM4C123GXL and two CAN-Transceivers I had, MCP2562. I activated dynamic interrupt vectoring in both programs and plugged a 120Ohm resistor into both ends. I also made sure that the pins used in the example program corresponded with my wiring (in fact, I didn't have to change anything here: PB5 as TX and PB4 as RX).

The sending process seems to work properly. I measured TX and RX on the sender and they are the same, as it should be, since there is only one sender. This should mean that the MCP2562 is connected and powered properly. The levels on CAN_H and CAN_l are fine as well.

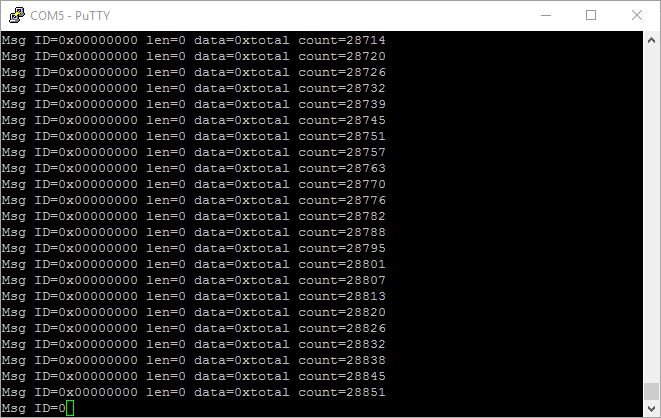

Then I plugged the receiver in, connected GND, CAN_H, CAN_L and decoded the RX and TX signals on the receiver using a logic analyzer. The messages arrive correctly (i.e., the second transceiver works as well). The receiver board also sends the ACK bit (which however doesn't seem to be received by my sender). Still, all I get to see on the serial output are Zeros.

When I disconnect the sender board or hold down the reset button, the receiver doesn't receive anything, so at least, there is some correlation.

Interestingly, when I change the system clock divider on one of the boards, the other one actually receives something (wrong data; but still different than zero). Is there some sort of synchronization problem?

I tried to lower the bit rate to 125,000 (on both boards), but no result.

I'm very much looking forward to any ideas!

I included a sketch of my wiring, as well as my programs.

//*****************************************************************************

//

// simple_rx.c - Example demonstrating simple CAN message reception.

//

// Copyright (c) 2010-2016 Texas Instruments Incorporated. All rights reserved.

// Software License Agreement

//

// Redistribution and use in source and binary forms, with or without

// modification, are permitted provided that the following conditions

// are met:

//

// Redistributions of source code must retain the above copyright

// notice, this list of conditions and the following disclaimer.

//

// Redistributions in binary form must reproduce the above copyright

// notice, this list of conditions and the following disclaimer in the

// documentation and/or other materials provided with the

// distribution.

//

// Neither the name of Texas Instruments Incorporated nor the names of

// its contributors may be used to endorse or promote products derived

// from this software without specific prior written permission.

//

// THIS SOFTWARE IS PROVIDED BY THE COPYRIGHT HOLDERS AND CONTRIBUTORS

// "AS IS" AND ANY EXPRESS OR IMPLIED WARRANTIES, INCLUDING, BUT NOT

// LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR

// A PARTICULAR PURPOSE ARE DISCLAIMED. IN NO EVENT SHALL THE COPYRIGHT

// OWNER OR CONTRIBUTORS BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL,

// SPECIAL, EXEMPLARY, OR CONSEQUENTIAL DAMAGES (INCLUDING, BUT NOT

// LIMITED TO, PROCUREMENT OF SUBSTITUTE GOODS OR SERVICES; LOSS OF USE,

// DATA, OR PROFITS; OR BUSINESS INTERRUPTION) HOWEVER CAUSED AND ON ANY

// THEORY OF LIABILITY, WHETHER IN CONTRACT, STRICT LIABILITY, OR TORT

// (INCLUDING NEGLIGENCE OR OTHERWISE) ARISING IN ANY WAY OUT OF THE USE

// OF THIS SOFTWARE, EVEN IF ADVISED OF THE POSSIBILITY OF SUCH DAMAGE.

//

// This is part of revision 2.1.3.156 of the Tiva Firmware Development Package.

//

//*****************************************************************************

#include <stdbool.h>

#include <stdint.h>

#include "inc/hw_can.h"

#include "inc/hw_ints.h"

#include "inc/hw_memmap.h"

#include "inc/hw_types.h"

#include "driverlib/can.h"

#include "driverlib/gpio.h"

#include "driverlib/interrupt.h"

#include "driverlib/pin_map.h"

#include "driverlib/sysctl.h"

#include "driverlib/uart.h"

#include "utils/uartstdio.h"

//*****************************************************************************

//

//! \addtogroup can_examples_list

//! <h1>Simple CAN RX (simple_rx)</h1>

//!

//! This example shows the basic setup of CAN in order to receive messages

//! from the CAN bus. The CAN peripheral is configured to receive messages

//! with any CAN ID and then print the message contents to the console.

//!

//! This example uses the following peripherals and I/O signals. You must

//! review these and change as needed for your own board:

//! - CAN0 peripheral

//! - GPIO port B peripheral (for CAN0 pins)

//! - CAN0RX - PB4

//! - CAN0TX - PB5

//!

//! The following UART signals are configured only for displaying console

//! messages for this example. These are not required for operation of CAN.

//! - GPIO port A peripheral (for UART0 pins)

//! - UART0RX - PA0

//! - UART0TX - PA1

//!

//! This example uses the following interrupt handlers. To use this example

//! in your own application you must add these interrupt handlers to your

//! vector table.

//! - INT_CAN0 - CANIntHandler

//

//*****************************************************************************

//*****************************************************************************

//

// A counter that keeps track of the number of times the RX interrupt has

// occurred, which should match the number of messages that were received.

//

//*****************************************************************************

volatile uint32_t g_ui32MsgCount = 0;

//*****************************************************************************

//

// A flag for the interrupt handler to indicate that a message was received.

//

//*****************************************************************************

volatile bool g_bRXFlag = 0;

//*****************************************************************************

//

// A flag to indicate that some reception error occurred.

//

//*****************************************************************************

volatile bool g_bErrFlag = 0;

//*****************************************************************************

//

// This function sets up UART0 to be used for a console to display information

// as the example is running.

//

//*****************************************************************************

void

InitConsole(void)

{

//

// Enable GPIO port A which is used for UART0 pins.

// TODO: change this to whichever GPIO port you are using.

//

SysCtlPeripheralEnable(SYSCTL_PERIPH_GPIOA);

//

// Configure the pin muxing for UART0 functions on port A0 and A1.

// This step is not necessary if your part does not support pin muxing.

// TODO: change this to select the port/pin you are using.

//

GPIOPinConfigure(GPIO_PA0_U0RX);

GPIOPinConfigure(GPIO_PA1_U0TX);

//

// Enable UART0 so that we can configure the clock.

//

SysCtlPeripheralEnable(SYSCTL_PERIPH_UART0);

//

// Use the internal 16MHz oscillator as the UART clock source.

//

UARTClockSourceSet(UART0_BASE, UART_CLOCK_PIOSC);

//

// Select the alternate (UART) function for these pins.

// TODO: change this to select the port/pin you are using.

//

GPIOPinTypeUART(GPIO_PORTA_BASE, GPIO_PIN_0 | GPIO_PIN_1);

//

// Initialize the UART for console I/O.

//

UARTStdioConfig(0, 115200, 16000000);

}

//*****************************************************************************

//

// This function is the interrupt handler for the CAN peripheral. It checks

// for the cause of the interrupt, and maintains a count of all messages that

// have been received.

//

//*****************************************************************************

void

CANIntHandler(void)

{

uint32_t ui32Status;

//

// Read the CAN interrupt status to find the cause of the interrupt

//

ui32Status = CANIntStatus(CAN0_BASE, CAN_INT_STS_CAUSE);

//

// If the cause is a controller status interrupt, then get the status

//

if(ui32Status == CAN_INT_INTID_STATUS)

{

//

// Read the controller status. This will return a field of status

// error bits that can indicate various errors. Error processing

// is not done in this example for simplicity. Refer to the

// API documentation for details about the error status bits.

// The act of reading this status will clear the interrupt.

//

ui32Status = CANStatusGet(CAN0_BASE, CAN_STS_CONTROL);

//

// Set a flag to indicate some errors may have occurred.

//

g_bErrFlag = 1;

}

//

// Check if the cause is message object 1, which what we are using for

// receiving messages.

//

else if(ui32Status == 1)

{

//

// Getting to this point means that the RX interrupt occurred on

// message object 1, and the message reception is complete. Clear the

// message object interrupt.

//

CANIntClear(CAN0_BASE, 1);

//

// Increment a counter to keep track of how many messages have been

// received. In a real application this could be used to set flags to

// indicate when a message is received.

//

g_ui32MsgCount++;

//

// Set flag to indicate received message is pending.

//

g_bRXFlag = 1;

//

// Since a message was received, clear any error flags.

//

g_bErrFlag = 0;

}

//

// Otherwise, something unexpected caused the interrupt. This should

// never happen.

//

else

{

//

// Spurious interrupt handling can go here.

//

}

}

//*****************************************************************************

//

// Configure the CAN and enter a loop to receive CAN messages.

//

//*****************************************************************************

int

main(void)

{

#if defined(TARGET_IS_TM4C129_RA0) || \

defined(TARGET_IS_TM4C129_RA1) || \

defined(TARGET_IS_TM4C129_RA2)

uint32_t ui32SysClock;

#endif

tCANMsgObject sCANMessage;

uint8_t pui8MsgData[8];

//

// Set the clocking to run directly from the external crystal/oscillator.

// TODO: The SYSCTL_XTAL_ value must be changed to match the value of the

// crystal used on your board.

//

#if defined(TARGET_IS_TM4C129_RA0) || \

defined(TARGET_IS_TM4C129_RA1) || \

defined(TARGET_IS_TM4C129_RA2)

ui32SysClock = SysCtlClockFreqSet((SYSCTL_XTAL_25MHZ |

SYSCTL_OSC_MAIN |

SYSCTL_USE_OSC)

25000000);

#else

SysCtlClockSet(SYSCTL_SYSDIV_1 | SYSCTL_USE_OSC | SYSCTL_OSC_MAIN |

SYSCTL_XTAL_16MHZ);

#endif

//

// Set up the serial console to use for displaying messages. This is

// just for this example program and is not needed for CAN operation.

//

InitConsole();

//

// For this example CAN0 is used with RX and TX pins on port B4 and B5.

// The actual port and pins used may be different on your part, consult

// the data sheet for more information.

// GPIO port B needs to be enabled so these pins can be used.

// TODO: change this to whichever GPIO port you are using

//

SysCtlPeripheralEnable(SYSCTL_PERIPH_GPIOB);

//

// Configure the GPIO pin muxing to select CAN0 functions for these pins.

// This step selects which alternate function is available for these pins.

// This is necessary if your part supports GPIO pin function muxing.

// Consult the data sheet to see which functions are allocated per pin.

// TODO: change this to select the port/pin you are using

//

GPIOPinConfigure(GPIO_PB4_CAN0RX);

GPIOPinConfigure(GPIO_PB5_CAN0TX);

//

// Enable the alternate function on the GPIO pins. The above step selects

// which alternate function is available. This step actually enables the

// alternate function instead of GPIO for these pins.

// TODO: change this to match the port/pin you are using

//

GPIOPinTypeCAN(GPIO_PORTB_BASE, GPIO_PIN_4 | GPIO_PIN_5);

//

// The GPIO port and pins have been set up for CAN. The CAN peripheral

// must be enabled.

//

SysCtlPeripheralEnable(SYSCTL_PERIPH_CAN0);

//

// Initialize the CAN controller

//

CANInit(CAN0_BASE);

//

// Set up the bit rate for the CAN bus. This function sets up the CAN

// bus timing for a nominal configuration. You can achieve more control

// over the CAN bus timing by using the function CANBitTimingSet() instead

// of this one, if needed.

// In this example, the CAN bus is set to 500 kHz. In the function below,

// the call to SysCtlClockGet() or ui32SysClock is used to determine the

// clock rate that is used for clocking the CAN peripheral. This can be

// replaced with a fixed value if you know the value of the system clock,

// saving the extra function call. For some parts, the CAN peripheral is

// clocked by a fixed 8 MHz regardless of the system clock in which case

// the call to SysCtlClockGet() or ui32SysClock should be replaced with

// 8000000. Consult the data sheet for more information about CAN

// peripheral clocking.

//

#if defined(TARGET_IS_TM4C129_RA0) || \

defined(TARGET_IS_TM4C129_RA1) || \

defined(TARGET_IS_TM4C129_RA2)

CANBitRateSet(CAN0_BASE, ui32SysClock, 500000);

#else

CANBitRateSet(CAN0_BASE, SysCtlClockGet(), 125000);

#endif

//

// Enable interrupts on the CAN peripheral. This example uses static

// allocation of interrupt handlers which means the name of the handler

// is in the vector table of startup code. If you want to use dynamic

// allocation of the vector table, then you must also call CANIntRegister()

// here.

//

CANIntRegister(CAN0_BASE, CANIntHandler); // if using dynamic vectors

//

CANIntEnable(CAN0_BASE, CAN_INT_MASTER | CAN_INT_ERROR | CAN_INT_STATUS);

//

// Enable the CAN interrupt on the processor (NVIC).

//

IntEnable(INT_CAN0);

//

// Enable the CAN for operation.

//

CANEnable(CAN0_BASE);

//

// Initialize a message object to be used for receiving CAN messages with

// any CAN ID. In order to receive any CAN ID, the ID and mask must both

// be set to 0, and the ID filter enabled.

//

sCANMessage.ui32MsgID = 1;

sCANMessage.ui32MsgIDMask = 0xFF;

sCANMessage.ui32Flags = MSG_OBJ_RX_INT_ENABLE | MSG_OBJ_USE_ID_FILTER;

sCANMessage.ui32MsgLen = 8;

//

// Now load the message object into the CAN peripheral. Once loaded the

// CAN will receive any message on the bus, and an interrupt will occur.

// Use message object 1 for receiving messages (this is not the same as

// the CAN ID which can be any value in this example).

//

CANMessageSet(CAN0_BASE, 1, &sCANMessage, MSG_OBJ_TYPE_RX);

//

// Enter loop to process received messages. This loop just checks a flag

// that is set by the interrupt handler, and if set it reads out the

// message and displays the contents. This is not a robust method for

// processing incoming CAN data and can only handle one messages at a time.

// If many messages are being received close together, then some messages

// may be dropped. In a real application, some other method should be used

// for queuing received messages in a way to ensure they are not lost. You

// can also make use of CAN FIFO mode which will allow messages to be

// buffered before they are processed.

//

for(;;)

{

unsigned int uIdx;

//

// If the flag is set, that means that the RX interrupt occurred and

// there is a message ready to be read from the CAN

//

if(g_bRXFlag)

{

//

// Reuse the same message object that was used earlier to configure

// the CAN for receiving messages. A buffer for storing the

// received data must also be provided, so set the buffer pointer

// within the message object.

//

sCANMessage.pui8MsgData = pui8MsgData;

//

// Read the message from the CAN. Message object number 1 is used

// (which is not the same thing as CAN ID). The interrupt clearing

// flag is not set because this interrupt was already cleared in

// the interrupt handler.

//

CANMessageGet(CAN0_BASE, 1, &sCANMessage, 0);

//

// Clear the pending message flag so that the interrupt handler can

// set it again when the next message arrives.

//

g_bRXFlag = 0;

//

// Check to see if there is an indication that some messages were

// lost.

//

if(sCANMessage.ui32Flags & MSG_OBJ_DATA_LOST)

{

UARTprintf("CAN message loss detected\n");

}

//

// Print out the contents of the message that was received.

//

UARTprintf("Msg ID=0x%08X len=%u data=0x",

sCANMessage.ui32MsgID, sCANMessage.ui32MsgLen);

for(uIdx = 0; uIdx < sCANMessage.ui32MsgLen; uIdx++)

{

UARTprintf("%02X ", pui8MsgData[uIdx]);

}

UARTprintf("total count=%u\n", g_ui32MsgCount);

}

}

//

// Return no errors

//

return(0);

}

//*****************************************************************************

//

// simple_tx.c - Example demonstrating simple CAN message transmission.

//

// Copyright (c) 2010-2016 Texas Instruments Incorporated. All rights reserved.

// Software License Agreement

//

// Redistribution and use in source and binary forms, with or without

// modification, are permitted provided that the following conditions

// are met:

//

// Redistributions of source code must retain the above copyright

// notice, this list of conditions and the following disclaimer.

//

// Redistributions in binary form must reproduce the above copyright

// notice, this list of conditions and the following disclaimer in the

// documentation and/or other materials provided with the

// distribution.

//

// Neither the name of Texas Instruments Incorporated nor the names of

// its contributors may be used to endorse or promote products derived

// from this software without specific prior written permission.

//

// THIS SOFTWARE IS PROVIDED BY THE COPYRIGHT HOLDERS AND CONTRIBUTORS

// "AS IS" AND ANY EXPRESS OR IMPLIED WARRANTIES, INCLUDING, BUT NOT

// LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR

// A PARTICULAR PURPOSE ARE DISCLAIMED. IN NO EVENT SHALL THE COPYRIGHT

// OWNER OR CONTRIBUTORS BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL,

// SPECIAL, EXEMPLARY, OR CONSEQUENTIAL DAMAGES (INCLUDING, BUT NOT

// LIMITED TO, PROCUREMENT OF SUBSTITUTE GOODS OR SERVICES; LOSS OF USE,

// DATA, OR PROFITS; OR BUSINESS INTERRUPTION) HOWEVER CAUSED AND ON ANY

// THEORY OF LIABILITY, WHETHER IN CONTRACT, STRICT LIABILITY, OR TORT

// (INCLUDING NEGLIGENCE OR OTHERWISE) ARISING IN ANY WAY OUT OF THE USE

// OF THIS SOFTWARE, EVEN IF ADVISED OF THE POSSIBILITY OF SUCH DAMAGE.

//

// This is part of revision 2.1.3.156 of the Tiva Firmware Development Package.

//

//*****************************************************************************

#include <stdbool.h>

#include <stdint.h>

#include "inc/hw_can.h"

#include "inc/hw_ints.h"

#include "inc/hw_memmap.h"

#include "driverlib/can.h"

#include "driverlib/gpio.h"

#include "driverlib/interrupt.h"

#include "driverlib/pin_map.h"

#include "driverlib/sysctl.h"

#include "driverlib/uart.h"

#include "utils/uartstdio.h"

//*****************************************************************************

//

//! \addtogroup can_examples_list

//! <h1>Simple CAN TX (simple_tx)</h1>

//!

//! This example shows the basic setup of CAN in order to transmit messages

//! on the CAN bus. The CAN peripheral is configured to transmit messages

//! with a specific CAN ID. A message is then transmitted once per second,

//! using a simple delay loop for timing. The message that is sent is a 4

//! byte message that contains an incrementing pattern. A CAN interrupt

//! handler is used to confirm message transmission and count the number of

//! messages that have been sent.

//!

//! This example uses the following peripherals and I/O signals. You must

//! review these and change as needed for your own board:

//! - CAN0 peripheral

//! - GPIO Port B peripheral (for CAN0 pins)

//! - CAN0RX - PB4

//! - CAN0TX - PB5

//!

//! The following UART signals are configured only for displaying console

//! messages for this example. These are not required for operation of CAN.

//! - GPIO port A peripheral (for UART0 pins)

//! - UART0RX - PA0

//! - UART0TX - PA1

//!

//! This example uses the following interrupt handlers. To use this example

//! in your own application you must add these interrupt handlers to your

//! vector table.

//! - INT_CAN0 - CANIntHandler

//

//*****************************************************************************

//*****************************************************************************

//

// A counter that keeps track of the number of times the TX interrupt has

// occurred, which should match the number of TX messages that were sent.

//

//*****************************************************************************

volatile uint32_t g_ui32MsgCount = 0;

//*****************************************************************************

//

// A flag to indicate that some transmission error occurred.

//

//*****************************************************************************

volatile bool g_bErrFlag = 0;

//*****************************************************************************

//

// This function sets up UART0 to be used for a console to display information

// as the example is running.

//

//*****************************************************************************

void

InitConsole(void)

{

//

// Enable GPIO port A which is used for UART0 pins.

// TODO: change this to whichever GPIO port you are using.

//

SysCtlPeripheralEnable(SYSCTL_PERIPH_GPIOA);

//

// Configure the pin muxing for UART0 functions on port A0 and A1.

// This step is not necessary if your part does not support pin muxing.

// TODO: change this to select the port/pin you are using.

//

GPIOPinConfigure(GPIO_PA0_U0RX);

GPIOPinConfigure(GPIO_PA1_U0TX);

//

// Enable UART0 so that we can configure the clock.

//

SysCtlPeripheralEnable(SYSCTL_PERIPH_UART0);

//

// Use the internal 16MHz oscillator as the UART clock source.

//

UARTClockSourceSet(UART0_BASE, UART_CLOCK_PIOSC);

//

// Select the alternate (UART) function for these pins.

// TODO: change this to select the port/pin you are using.

//

GPIOPinTypeUART(GPIO_PORTA_BASE, GPIO_PIN_0 | GPIO_PIN_1);

//

// Initialize the UART for console I/O.

//

UARTStdioConfig(0, 115200, 16000000);

}

//*****************************************************************************

//

// This function provides a 1 second delay using a simple polling method.

//

//*****************************************************************************

void

SimpleDelay(void)

{

//

// Delay cycles for 1 second

//

SysCtlDelay(16000000 / 3);

}

//*****************************************************************************

//

// This function is the interrupt handler for the CAN peripheral. It checks

// for the cause of the interrupt, and maintains a count of all messages that

// have been transmitted.

//

//*****************************************************************************

void

CANIntHandler(void)

{

uint32_t ui32Status;

//

// Read the CAN interrupt status to find the cause of the interrupt

//

ui32Status = CANIntStatus(CAN0_BASE, CAN_INT_STS_CAUSE);

//

// If the cause is a controller status interrupt, then get the status

//

if(ui32Status == CAN_INT_INTID_STATUS)

{

//

// Read the controller status. This will return a field of status

// error bits that can indicate various errors. Error processing

// is not done in this example for simplicity. Refer to the

// API documentation for details about the error status bits.

// The act of reading this status will clear the interrupt. If the

// CAN peripheral is not connected to a CAN bus with other CAN devices

// present, then errors will occur and will be indicated in the

// controller status.

//

ui32Status = CANStatusGet(CAN0_BASE, CAN_STS_CONTROL);

//

// Set a flag to indicate some errors may have occurred.

//

g_bErrFlag = 1;

}

//

// Check if the cause is message object 1, which what we are using for

// sending messages.

//

else if(ui32Status == 1)

{

//

// Getting to this point means that the TX interrupt occurred on

// message object 1, and the message TX is complete. Clear the

// message object interrupt.

//

CANIntClear(CAN0_BASE, 1);

//

// Increment a counter to keep track of how many messages have been

// sent. In a real application this could be used to set flags to

// indicate when a message is sent.

//

g_ui32MsgCount++;

//

// Since the message was sent, clear any error flags.

//

g_bErrFlag = 0;

}

//

// Otherwise, something unexpected caused the interrupt. This should

// never happen.

//

else

{

//

// Spurious interrupt handling can go here.

//

}

}

//*****************************************************************************

//

// Configure the CAN and enter a loop to transmit periodic CAN messages.

//

//*****************************************************************************

int

main(void)

{

#if defined(TARGET_IS_TM4C129_RA0) || \

defined(TARGET_IS_TM4C129_RA1) || \

defined(TARGET_IS_TM4C129_RA2)

uint32_t ui32SysClock;

#endif

tCANMsgObject sCANMessage;

uint32_t ui32MsgData;

uint8_t *pui8MsgData;

pui8MsgData = (uint8_t *)&ui32MsgData;

//

// Set the clocking to run directly from the external crystal/oscillator.

// TODO: The SYSCTL_XTAL_ value must be changed to match the value of the

// crystal on your board.

//

#if defined(TARGET_IS_TM4C129_RA0) || \

defined(TARGET_IS_TM4C129_RA1) || \

defined(TARGET_IS_TM4C129_RA2)

ui32SysClock = SysCtlClockFreqSet((SYSCTL_XTAL_25MHZ |

SYSCTL_OSC_MAIN |

SYSCTL_USE_OSC)

25000000);

#else

SysCtlClockSet(SYSCTL_SYSDIV_1 | SYSCTL_USE_OSC | SYSCTL_OSC_MAIN |

SYSCTL_XTAL_16MHZ);

#endif

//

// Set up the serial console to use for displaying messages. This is

// just for this example program and is not needed for CAN operation.

//

InitConsole();

//

// For this example CAN0 is used with RX and TX pins on port B4 and B5.

// The actual port and pins used may be different on your part, consult

// the data sheet for more information.

// GPIO port B needs to be enabled so these pins can be used.

// TODO: change this to whichever GPIO port you are using

//

SysCtlPeripheralEnable(SYSCTL_PERIPH_GPIOB);

//

// Configure the GPIO pin muxing to select CAN0 functions for these pins.

// This step selects which alternate function is available for these pins.

// This is necessary if your part supports GPIO pin function muxing.

// Consult the data sheet to see which functions are allocated per pin.

// TODO: change this to select the port/pin you are using

//

GPIOPinConfigure(GPIO_PB4_CAN0RX);

GPIOPinConfigure(GPIO_PB5_CAN0TX);

//

// Enable the alternate function on the GPIO pins. The above step selects

// which alternate function is available. This step actually enables the

// alternate function instead of GPIO for these pins.

// TODO: change this to match the port/pin you are using

//

GPIOPinTypeCAN(GPIO_PORTB_BASE, GPIO_PIN_4 | GPIO_PIN_5);

//

// The GPIO port and pins have been set up for CAN. The CAN peripheral

// must be enabled.

//

SysCtlPeripheralEnable(SYSCTL_PERIPH_CAN0);

//

// Initialize the CAN controller

//

CANInit(CAN0_BASE);

//

// Set up the bit rate for the CAN bus. This function sets up the CAN

// bus timing for a nominal configuration. You can achieve more control

// over the CAN bus timing by using the function CANBitTimingSet() instead

// of this one, if needed.

// In this example, the CAN bus is set to 500 kHz. In the function below,

// the call to SysCtlClockGet() or ui32SysClock is used to determine the

// clock rate that is used for clocking the CAN peripheral. This can be

// replaced with a fixed value if you know the value of the system clock,

// saving the extra function call. For some parts, the CAN peripheral is

// clocked by a fixed 8 MHz regardless of the system clock in which case

// the call to SysCtlClockGet() or ui32SysClock should be replaced with

// 8000000. Consult the data sheet for more information about CAN

// peripheral clocking.

//

#if defined(TARGET_IS_TM4C129_RA0) || \

defined(TARGET_IS_TM4C129_RA1) || \

defined(TARGET_IS_TM4C129_RA2)

CANBitRateSet(CAN0_BASE, ui32SysClock, 500000);

#else

CANBitRateSet(CAN0_BASE, SysCtlClockGet(), 125000);

#endif

//

// Enable interrupts on the CAN peripheral. This example uses static

// allocation of interrupt handlers which means the name of the handler

// is in the vector table of startup code. If you want to use dynamic

// allocation of the vector table, then you must also call CANIntRegister()

// here.

//

CANIntRegister(CAN0_BASE, CANIntHandler); // if using dynamic vectors

//

CANIntEnable(CAN0_BASE, CAN_INT_MASTER | CAN_INT_ERROR | CAN_INT_STATUS);

//

// Enable the CAN interrupt on the processor (NVIC).

//

IntEnable(INT_CAN0);

//

// Enable the CAN for operation.

//

CANEnable(CAN0_BASE);

//

// Initialize the message object that will be used for sending CAN

// messages. The message will be 4 bytes that will contain an incrementing

// value. Initially it will be set to 0.

//

ui32MsgData = 0;

sCANMessage.ui32MsgID = 1;

sCANMessage.ui32MsgIDMask = 0;

sCANMessage.ui32Flags = MSG_OBJ_TX_INT_ENABLE;

sCANMessage.ui32MsgLen = 4;

sCANMessage.pui8MsgData = pui8MsgData;

//

// Enter loop to send messages. A new message will be sent once per

// second. The 4 bytes of message content will be treated as an uint32_t

// and incremented by one each time.

//

while(1)

{

//

// Print a message to the console showing the message count and the

// contents of the message being sent.

//

UARTprintf("Sending msg: 0x%02X %02X %02X %02X",

pui8MsgData[0], pui8MsgData[1], pui8MsgData[2],

pui8MsgData[3]);

//

// Send the CAN message using object number 1 (not the same thing as

// CAN ID, which is also 1 in this example). This function will cause

// the message to be transmitted right away.

//

CANMessageSet(CAN0_BASE, 1, &sCANMessage, MSG_OBJ_TYPE_TX);

//

// Now wait 1 second before continuing

//

SimpleDelay();

//

// Check the error flag to see if errors occurred

//

if(g_bErrFlag)

{

UARTprintf(" error - cable connected?\n");

}

else

{

//

// If no errors then print the count of message sent

//

UARTprintf(" total count = %u\n", g_ui32MsgCount);

}

//

// Increment the value in the message data.

//

ui32MsgData++;

}

//

// Return no errors

//

return(0);

}