Hi

I'm using a flash parameter block for device configuration. (LM4F120, LaunchPad, Code Composer Studio, C, Firmware development package Flash API)

I want my embedded device to ship with a' factory default' configuration which can later be modified in the field by the user. Pretty standard stuff.

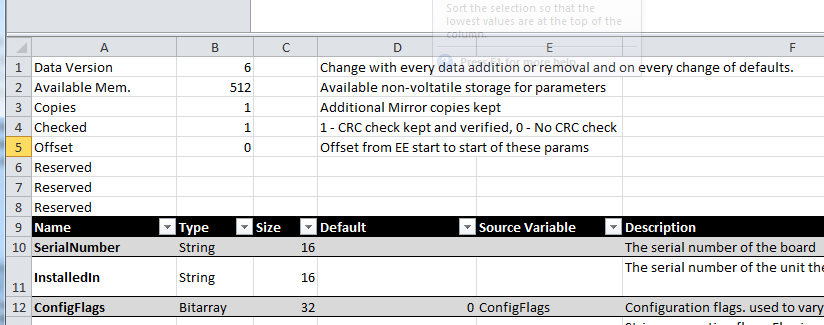

The parameter block is a big C struct. I can initialize the struct in firmware to the 'factory default' values by assigning values to each element of the struct. This is self-documenting, and easy to read and modify.

The initialization section of the firmware code can then write this struct containing these hard-coded values to flash .

The problem is the flash will be initialized every time the firmware initialization section is RUN, which is every time it is BOOTED or powered up. This obviously defeats the whole purpose of flash.

Clearly, I need the flash parameter block initialized only when the part is PROGRAMMED.

So, what is the 'right way' to do this in Code Composer Studio?

Thanks in advance for your help

-Adam