Other Parts Discussed in Thread: DRV8304,

If you are new to motor driver systems, and wondering what people mean by external versus integrated MOSFET architectures, then you have landed on the right FAQ page! Even as an experienced motor system designer, many of us have often wondered which MOSFET architecture to choose for a given system. In this FAQ, I will introduce you to both the architectures of Power MOSFETs. Although this FAQ is written with 3-phase BLDC system in mind, the concept can be easily scaled to different types of DC motor systems like single-phase BLDC motor, brushed DC or stepper motors.

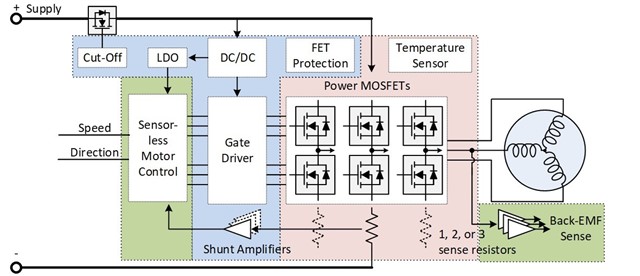

Figure 1: Typical Sensorless BLDC Motor System

The figure 1 shows a typical sensorless BLDC motor system. The components highlighted in BLUE are typically part of gate driver Integrated Circuits (ICs), where power MOSFETs are placed external to the IC on the board. When a gate driver IC includes components highlighted in RED as well, the IC is called Motor Driver or Integrated FET Driver. The components highlighted in GREEN are part of motor controller. We will focus our discussion on gate driver and motor driver architecture.

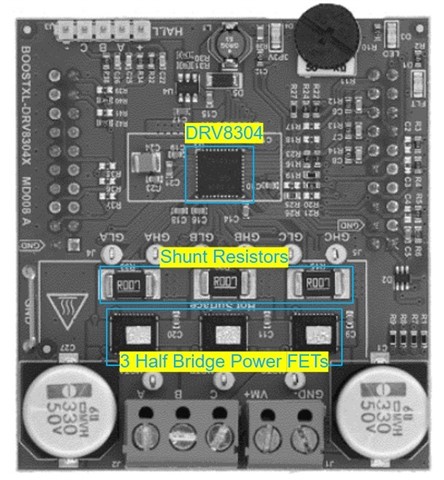

Gate Driver Architecture: An external MOSFET based architecture gives system designers the flexibility to use the same driver and control design for a wide range of applications, by choosing different MOSFETs to scale power levels. Typically, a MOSFET with higher current rating will have larger package size to accommodate the lower R(ON) of the MOSFET and deliver better thermal performance. System designer can choose different MOSFETs based on the system performance requirement and optimize the board size accordingly. As MOSFETs can be placed far apart on the board, gate driver architecture often provides better thermal performance. A drawback of gate driver-based architecture is the complexity of board design, due to 6 MOSFETs (for a 3-phase BLDC system) placement on the board. System designer also needs to worry about placement of MOSFETs with respect to gate driver IC in order to achieve system performance targets like lower EMI and noise. As compared to a motor driver solution of same power and voltage level, a gate driver system is much bigger due to higher number of components on the board. An example of gate driver board is DRV8304 EVM, which is 40-V BLDC system designed to deliver 15A current. The EVM board size is 61mm x 56mm (3233 sq. mm.). 6 MOSFETs occupy 2.5x times area on the board as compared to the gate driver IC!

Figure 2: DRV8304 EVM Board

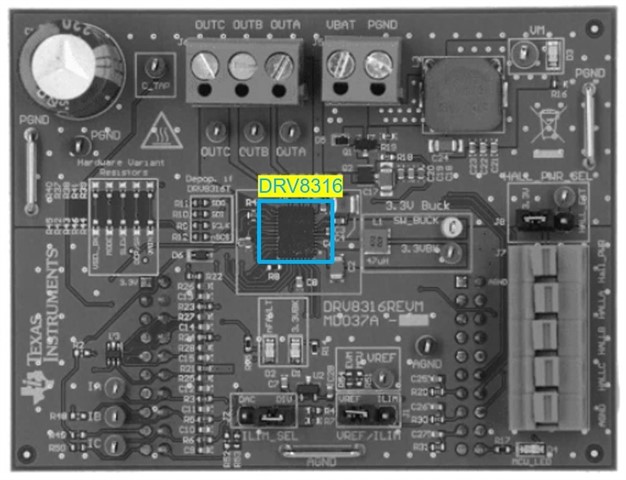

Motor Driver Architecture: An integrated MOSFETs based architecture provides simplicity of system board design and much smaller solution size as compared to a gate driver system. A motor driver system also enables faster design cycle as the system designers do not need to worry about optimizing the MOSFET gate drive techniques to achieve optimized EMI, noise or thermal performance. A motor driver IC developer would have already taken care of such problems while designing the IC! A typical motor driver IC can deliver anywhere between 1 to 10Amps of motor current. Due to 6 MOSFETs integrated in a small package (usually less than 10x10mm), motor driver ICs tend to have poor thermal performance. Designers need to choose a motor driver IC with lower FET R(ON) to meet their system thermal performance requirement. As a rule of thumb, approximately above 70-80W power levels, system designers start moving from a motor driver-based architecture to a gate driver-based architecture to achieve better thermal and power delivery performance. TI’s new BLDC motor driver, DRV8316 integrates 6 50mohm MOSFETs for a 3-phase BLDC system. The DRV8316 EVM board is 19.8mm x 16mm (317 sq. mm.), which is almost 10x smaller than the DRV8304 board for same motor voltage level!

Figure 3: DRV8316 EVM Board

In summary, a gate driver architecture-based system is flexible yet bigger and complex to design. A motor driver architecture-based system is simple, smaller and enables faster design cycle but may not meet all the thermal level requirements of the system. When it comes to a low power application, it is best to use motor driver architecture, specially the new DRV8316, which can deliver up to 70W of power in just 35 sq. mm. package

-- Prajkta Vyavahare (PV), Marketing and Applications manager for BLDC Motor Drives