Other Parts Discussed in Thread: CSD19536KTT

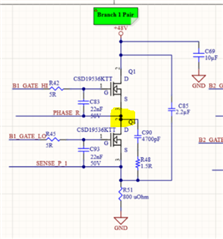

Hello, I'm here again with another revision of my DRV8353 circuit. The problem we're running into now is very high frequency (60-100MHz) oscillation on the switch nodes, seemingly unchangeable. For context, here's the schematic:

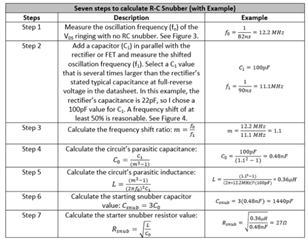

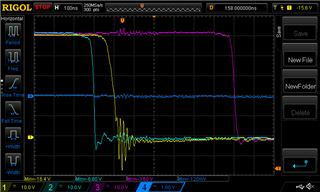

And on the switch nodes, we're seeing the yellow waveform below:

The VDrain node also shakes around, but not nearly as intensely (1V to 2V as opposed to -6V to -10V) We've tried everything we can think of to reduce the initial negative spike. TVS diodes are often too slow to cut this off. We tried putting a super-fast Schottky in parallel with the body diode (<10ns), but it didn't affect the waveform either. We tried increasing our snubber capacitors to 47nF. We then tried increasing the resistance of the snubber. We've tried a larger high side drain to low side source capacitor and a larger drain cap on the high side. It doesn't help. Slowing down the switching reduced the spike by a little, but as we increase the current, we still get close to -10V, which according to the datasheet is the maximum rating. We see this behavior on every switch node. What else can we try to do about this?

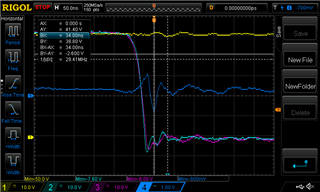

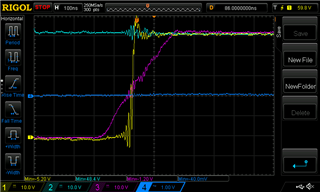

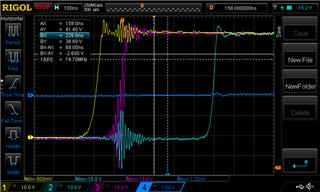

Separately, around 30A of motor current, this odd noise shows up on the switch nodes:

It doesn't happen every time we switch. It took a while to catch the particularly nasty ones such as the last one on the scope. I have to wonder, at that frequency, could this be due to our scope itself? Why is it only occasional? What can we do to handle noise that high frequency, when we also have to function up to 50A? The appearance of the envelope here is what confuses us most -- instead of having a peak and then ringing down, it increases and then decreases again.