Other Parts Discussed in Thread: DRV8353

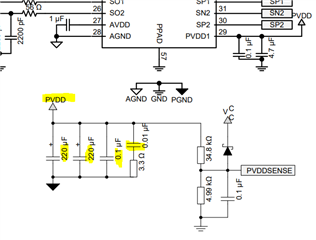

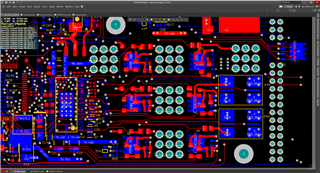

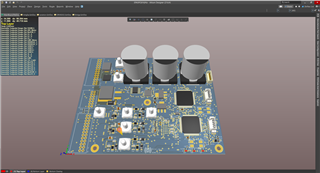

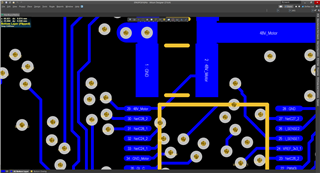

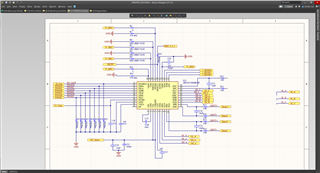

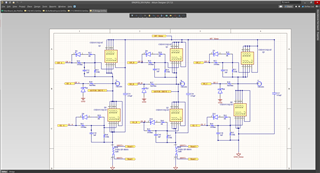

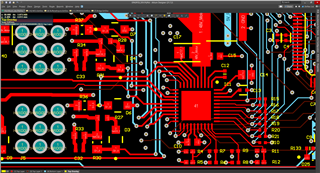

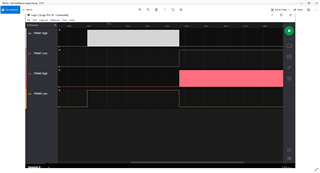

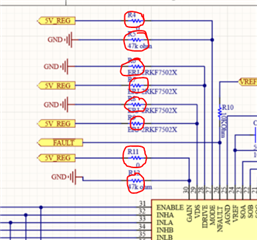

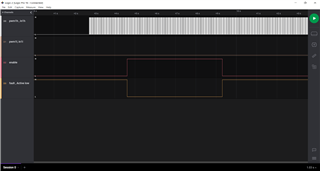

Currently in design / prototype we have 48 brushed motor design (with ability to go to 3 phase brushless ) We are seeing the same failure at 24v and at 48v. One of the failures is when we demand the motor to work then stop (energy still in system abrupt stop to go the other way ) The DRV8302 fails - the 5v stays up but it fails in such a way if i replace the chip its taken the PCB with it (6 layer , things are tight ). I do have a feeling I have a layout problem maybe some tracks need to be floods as I've looked at the design guide. The design guide shows for a 2 layer board , as I've said mine is 6 layer with a GND plain. We have also seen the track from 2.2uF caps to pin 29 blow (this could have been due to operator connecting a 48v inverter up to the board incorrectly) i am happy to post up Altium schematic and screen shots of layers / gerbers