Other Parts Discussed in Thread: DRV8434S

Hello

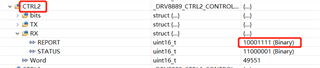

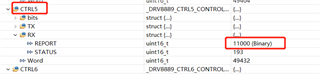

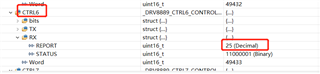

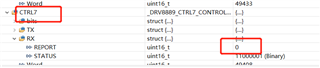

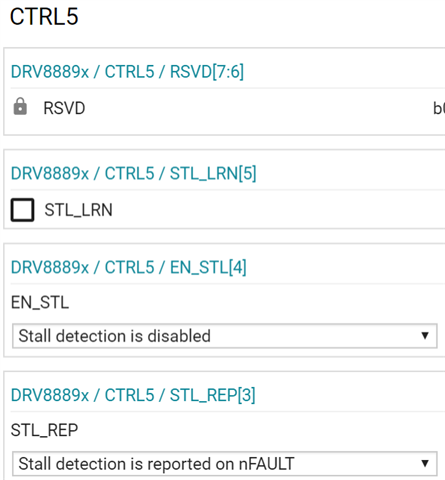

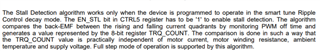

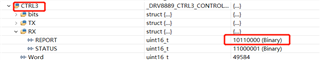

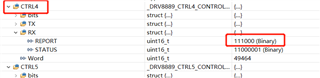

We use DRV8889-Q1 drive Stepper,when we use self learning function ,but bit "STL_LRN_OK",never goes to high.then we set some value for "STL_TH",For example, we will "STL_TH" is assigned to 4. By reading the value of the register, the occasional STL can be set to 1, which can not be detected most of the time. We have put "STL_TH "value of th is tried from 0 to 255, and it is the same every time: the FAULT Status Register" STL" or DIAG Status 2 Register ““STALL””can not be detected as 1. However, our customer requires that 100% can detect the“” STL“” setting as 1。

During the test, the stepper motor is as follows: when the stepper motor run normally, the operating current of the stepper motor is about 350mA. When locked rotor occurs, the current of the stepper motor is about 390ma to 420mA. I would like to ask how to improve the efficiency of seeing STL and achieve 100% detection? thanks。

Hello

Hello