Other Parts Discussed in Thread: MOTORWARE, DRV8305, LAUNCHXL-F28069M, DRV8308EVM

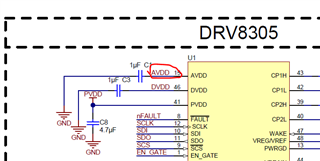

I have just bought a new BOOSTXL-DRV8305EVM board and am using the F28069M Launchpad.

While using Lab 01b and 02a from motorware, as soon as I enable the identify motor to 1, the red LED signifying the fault glows up in the booster pack.

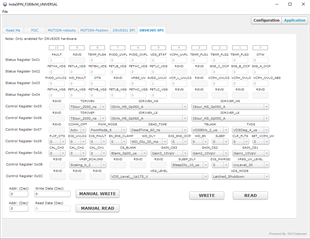

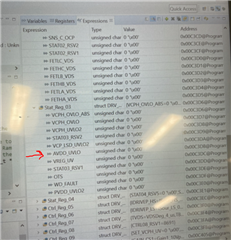

I have tried to check the fault condition by using the InstaSPIN_F2806xM_UNIVERSAL from GUI COmposer, DRV8305 SPI. The same problem gets repeated here, when I enable the system, there is no fault, but as soon as I run the motor the fault appears. I have attached the screenshot below.

Do let me know how to solve the problem?