Other Parts Discussed in Thread: DRV10987, DRV10987EVM, DRV10974, DRV10978, MCF8316A

Hi team,

Here's an issue from the customer may need your help:

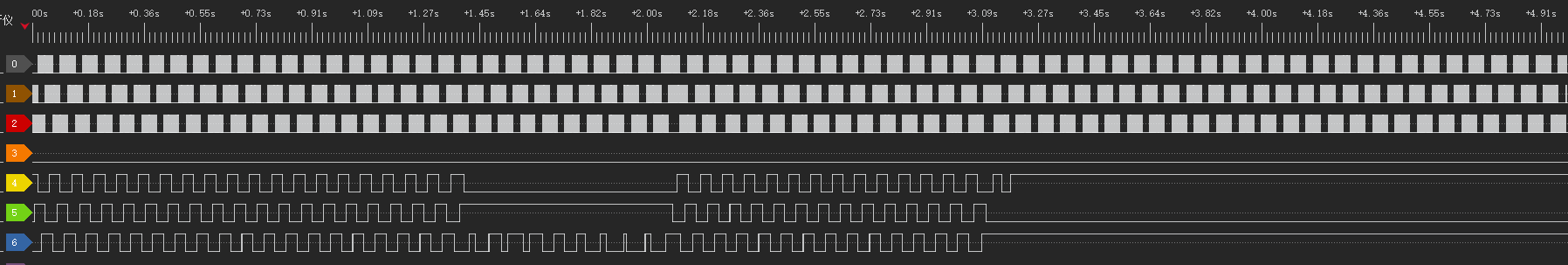

The DC brushless cavity motor uses a photoencoder to measure speed and the pwm is controlled by the speed ring pid. At low speed 1.5r/s~6r/s, running with load will experience jitter and frozen.

Does this chip not drive the motor to steady operation at low speed? Or is there any possible cause?

Could you help check this case? Thanks.

Best Regards,

Cherry