Other Parts Discussed in Thread: DRV8434

Hi,team,

My customer asked a question ,please help answer it,thank you.

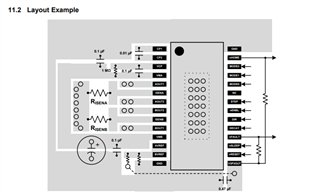

Equipped with your company's stepping motor driver (model: DRV8825)

I am designing a printed circuit board, but the stepping motor vibrates.

A problem has occurred.

If you have any advice, please let me know.

The customer was quite anxious to solve the problem and needed sincere suggestion.

Please note that the attachment is the test report.

Best Regards,

Katherine.TI製ステッピングモータドライバ不具合報告(20221216).pdf