Other Parts Discussed in Thread: MCF8315A

Hi,

The customer experienced a problem tuning the FOC.

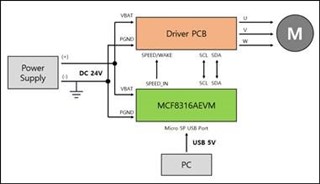

** H/W configuration **

- Customer Driver PCB / EVM B/D(GUI interface) / PC(GUI)

** MCF8316A-GUI **

Maximum rotational speed (Electrical) : 100 [Hz]

- 4 Pole / Max 3,000 [rpm]

- Current limit (Torque PI Loop): 2.5 [A]

- Results differ each time during the "Testing for successful start-up into closed loop" stage.

Case 1) Occasional MPET_BEMF_Fault, Hardware Lock Current Limit.

Case 2) In most cases, the drive is stopped/no action during closed loop operation as described below.

Case 3) Only one phase remains in a full turn-on state during initial alignment and start-up.

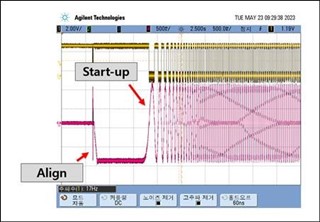

1. If you increase the rotational speed in the "Testing for successful start-up into closed loop" step, start the closed loop drive after aligning.

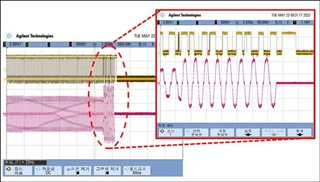

The waveforms below are Frequency Generator (FG) and U-phase phase current waveforms.

From the start of the drive, the phase current amplitude is gradually reduced (PI controlled) and the MPET estimates the motor parameters.

The Tuning Guide states that it may take 10 to 15 seconds, but this will continue for more than 1 minute.

Then suddenly the motor rattles and stops running, and the whole process stops.

There is no fault, and it does nothing at all.

If you zoom in on the waveform when it is rattling, the phase current rises as the Estimated Theta is distorted, and then the control stops.

Question :

Q1. For what reason can this phenomenon occur?

Q2. Occasionally, you may complete the "Testing for successful start-up into closed loop" process by tuning several times. At this point, there are some problems.

- The phase current waveform does not produce a complete Sin wave. Is there a way to do more detailed tuning?

- Increasing the speed command gradually increases the speed, but the increase is very slow.

(It takes about 2 minutes to set the maximum speed command from 0 rpm to 3000 rpm)

Do I have to tune the speed PID separately?

add : deleted