Hello Team!

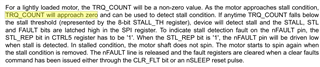

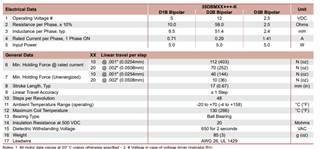

We are facing SPI communication issue with DRV8889 while setting up the stall detection register.

Is it always required to change the state of nSleep pin of the stepper driver to read/write the SPI register.

I have referred the sensorless stall detection application note as well and set all the parameters as required, still the registers are not getting properly updated.

Hope you can provide some solution over this.

Regards,

Agnideep.