Other Parts Discussed in Thread: DRV8711, DRV8462

Hi,

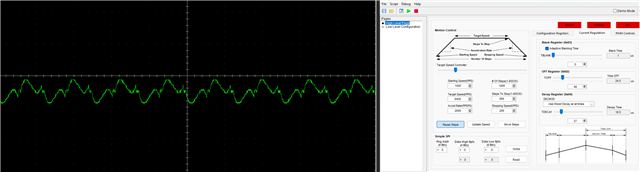

I am trying to calculate the drive register (OCPTH, OCPDEG, TDRIVEN, TDRIVEP, IDRIVEN, IDRIVEP) values for the DRV8711EVM evaluation module. I read the manual and the thread explaining how to do it, but it's not making that much sense to me. Please correct me if I'm wrong.

IDRIVEN and IDRIVEP are calculated the same. According to another thread it says use Qgd (nC) / Trise (nS) = IDRIVE (mA). It says to estimate the rise time, how do you do that? If I just use the default setting of 500nS. 5.9nC/500ns = 11.8mA. The closest settings are 100mA for IDRIVEN or 50mA for IDRIVEP. Is that correct?

TDRIVEN and TDRIVEP are the estimated rise times as mentioned above? So 500ns.

OCPTH - I am using a NEMA34 2 phase stepper with 4.2A per phase. According to the mosfet data sheet the RDSon value is 4.4 or 3.5 milliOhm, I'm not sure which one to use. The manual says use formula Iocp=OCPTH/RDSon. So 0.25(250mV)/0.0044ohms(4.4milliOhm) = 56.8Amps. Thats using the lowest setting and its still higher than the 4.2A so obviously I'm doing something wrong.

OCPDEG - I assume I start the lowest value and if I get nuicance trips due to inrush current then I increase this just enough to stop them.

Apologies as I am not an engineer, feel free to be blunt with me and tell me it's over my head.

Regards,

Nathan