Other Parts Discussed in Thread: , DRV8848

Hi Team,

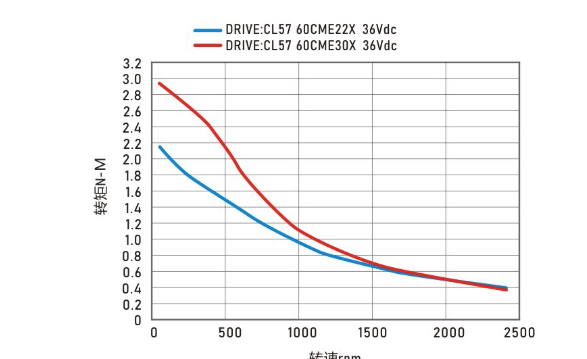

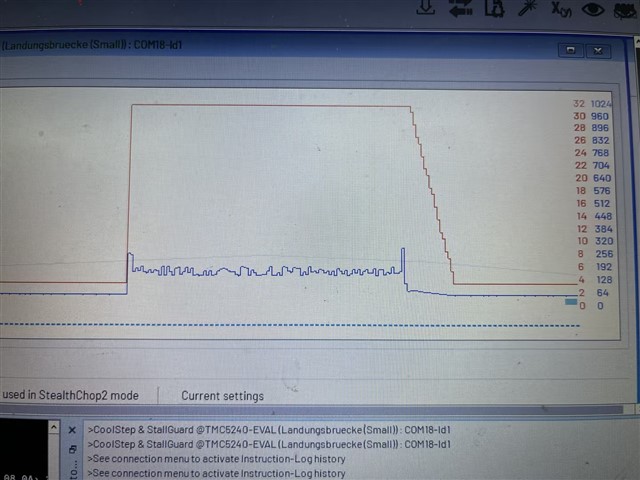

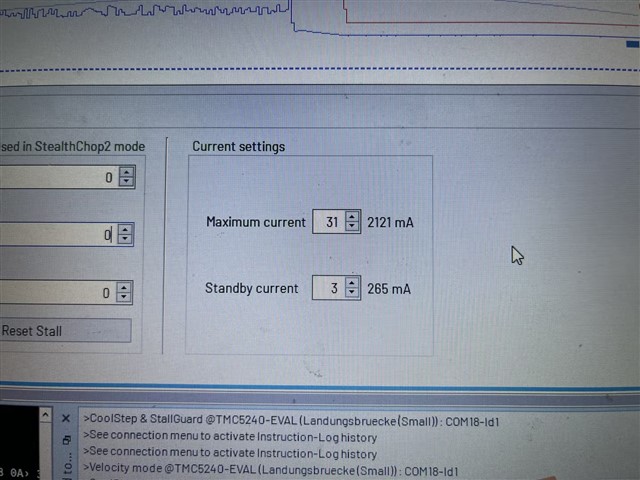

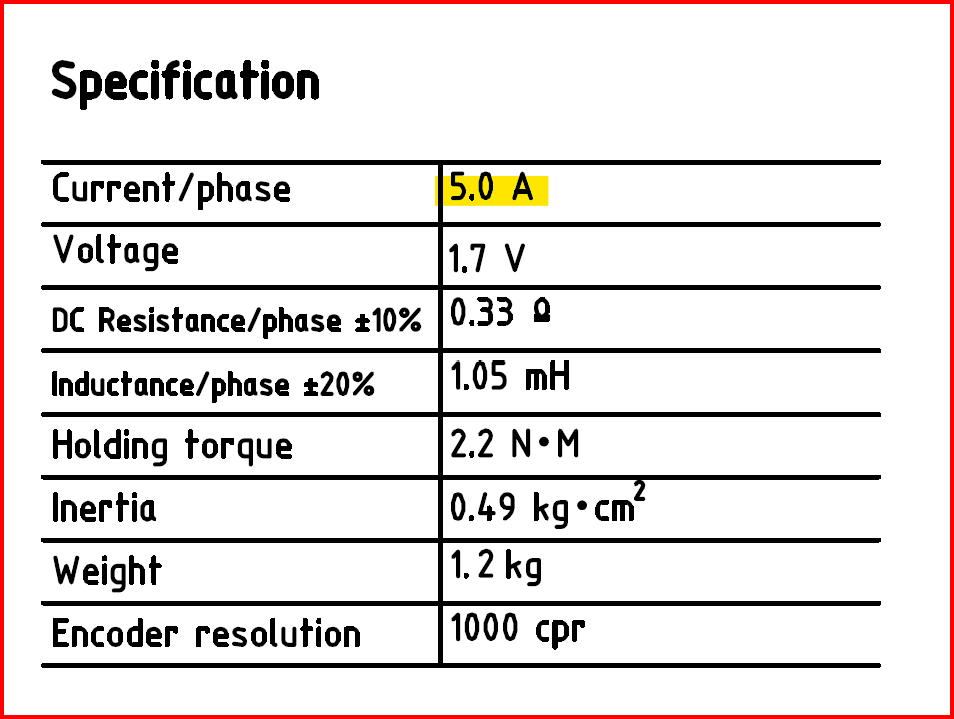

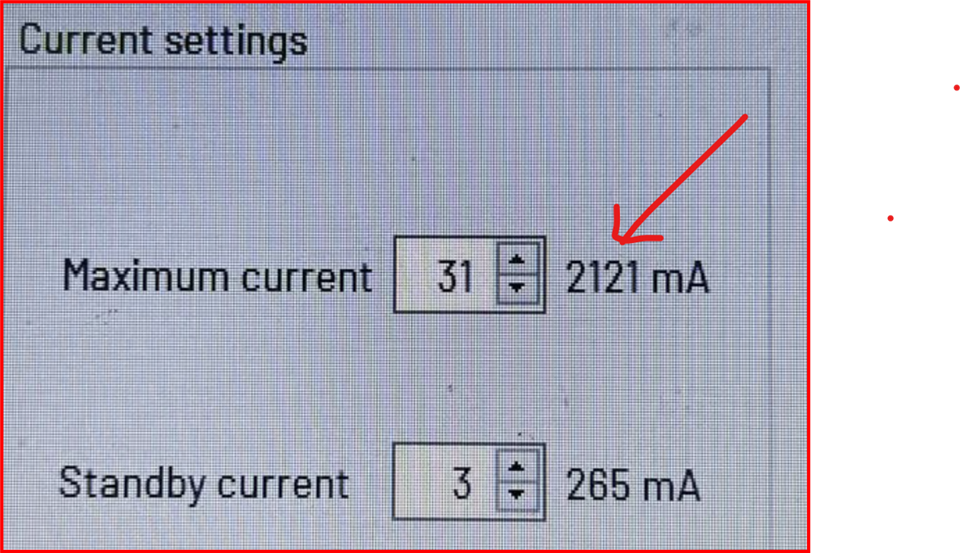

1. Use the DRV8462 driver chip, set it to HW mode, subdivide it into 32, and send PWM waves with a frequency above 20khz. The motor has a sound but cannot rotate. When the same subdivision is 128, when the frequency is above 80khz, the motor also makes sound but cannot rotate, and the maximum rotating speed is only 150rpm. What is the cause?

2. Using the DRV8462 driver chip SPI mode, the operating current is set to the maximum FFFFFFFF, the holding current is 7FFFFFFFF, there is no subdivision, and the motor speed can reach a maximum of 300rpm. Increasing the frequency also causes the problem that the motor makes a sound but cannot rotate, and the chip may even overheat to protect itself. What is the cause?

Regards,

Annie