Tool/software:

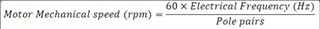

I am trying to use PN: MCF8316A to drive a BLDC motor at a speed of 75,000 rpm. First question - is this achievable based on allowed switching speeds of the FETs?

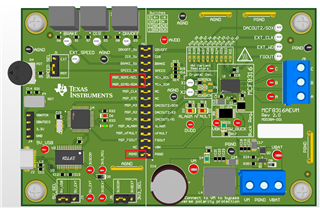

Second, I don't want to go through all the trouble of building out custom software / firmware if there is an easier way. I see that the GUI for the EVM board has a nice / easy interface to make all the configurations needed. Is it possible to use the GUI to configure a MCF8316A that is not on the EVM board? I am trying to design a first proof of concept device which requires a smaller form factor.

Thanks!

Joe Carlson