Other Parts Discussed in Thread: SN754410, LM339, NE555, LM393, DRV8962

Tool/software:

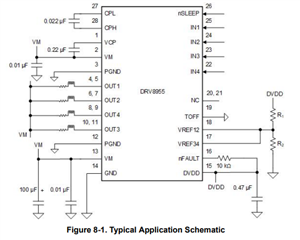

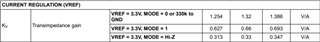

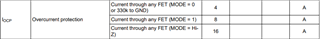

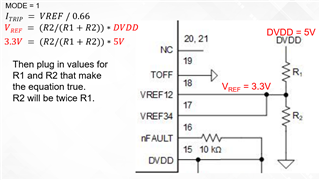

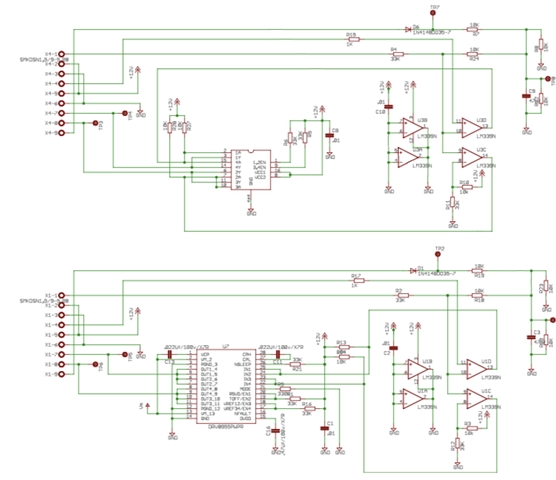

I believe I found an excellent choice for upgrading my motor driver however, no reference design exists and I couldn’t find one schematic that uses it, I studied the data sheet and came up with a possible solution.

The top circuit is my tried and true low power SN754410 motor driver and the bottom circuit is the potential higher power driver using the DRV8955.

If something isn’t right or needs adjustment let me know, if it won’t work and you know why I would appreciate the help since it’s been more than 20 years since I’ve done anything in this field so I’m kinda lost and looking for help.