Tool/software:

Hi team,

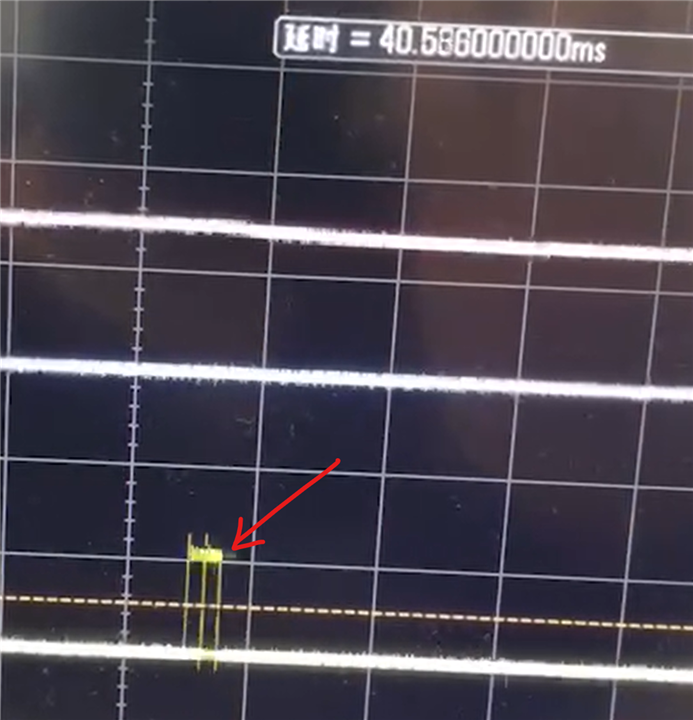

As the video shows, customer let 8889 learn the STALL_TH value to 0x17, and test stall condition. When TRQ_COUNT = 0x11, the STL and FAULT bit did not set to 1 which does not match the datasheet. Could you please help analyze what's the problem?

BR,

Bengi