Other Parts Discussed in Thread: DRV8323, DRV8353

Tool/software:

Hi,

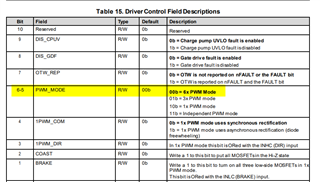

I am trying to run a 3-phase BLDC motor using the DRV8323 driver in 1xPWM mode with a Hall effect sensor. I am also using the Nucleo WB55RG board to generate a 20kHz PWM signal.

The motor is spinning, but there is audible noise, which decreases only at a 50% duty cycle. Additionally, the motor speed does not vary with changes in the duty cycle.

INHC= HIGH

INLC = HIGH

INHA = PWM

INLA,INHB,INLB = HALL sensor

ENABLE = HIGH