Other Parts Discussed in Thread: DRV8262,

Tool/software:

Hallo ich habe mich an folgendem Thread orientiert:

1. Did I control the correct pins?

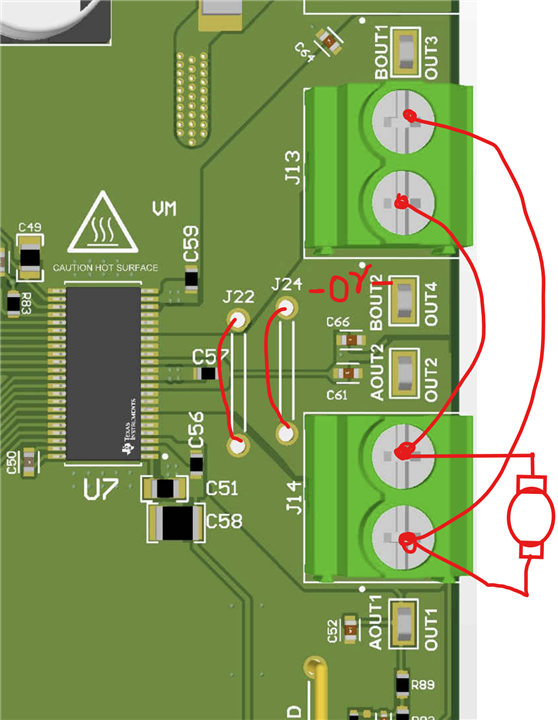

I have attached a picture of my setup showing which pins I have set to HIGH and LOW.

Despite the settings mentioned above (MODE1 high, MODE2 low), the driver shows no response.

Is it possible that I've connected the wrong pins?

Or is there something else I need to consider?

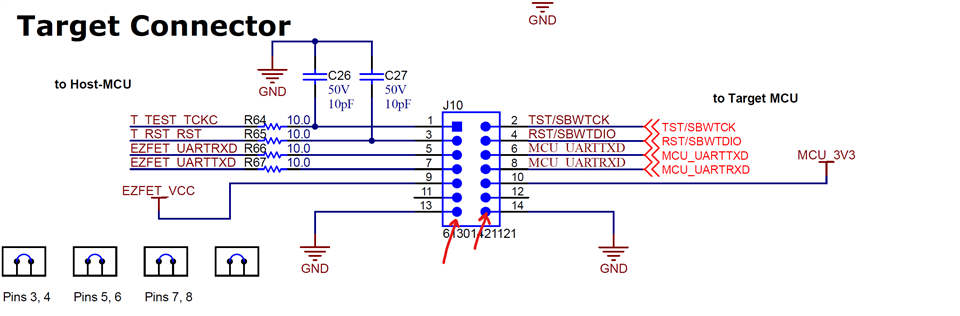

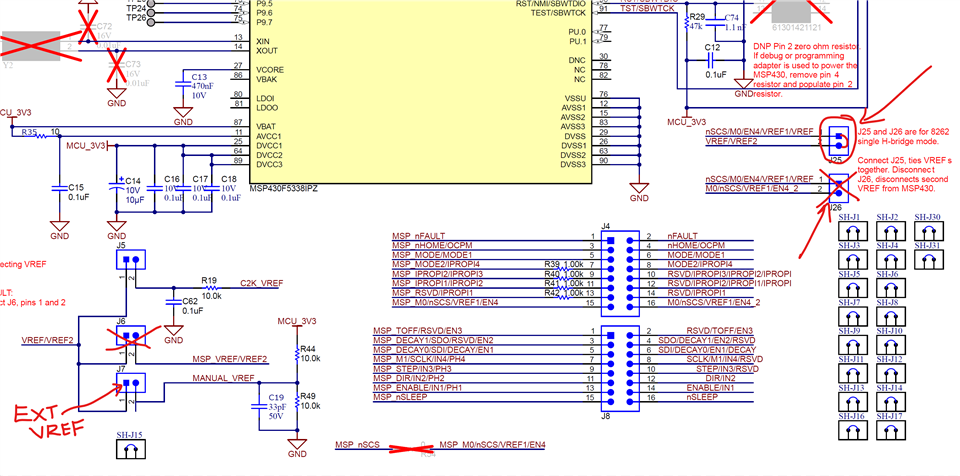

MODE1 and MODE2 pins looks correct in the picture you shared. See below from the EVM User's Guide page-45.

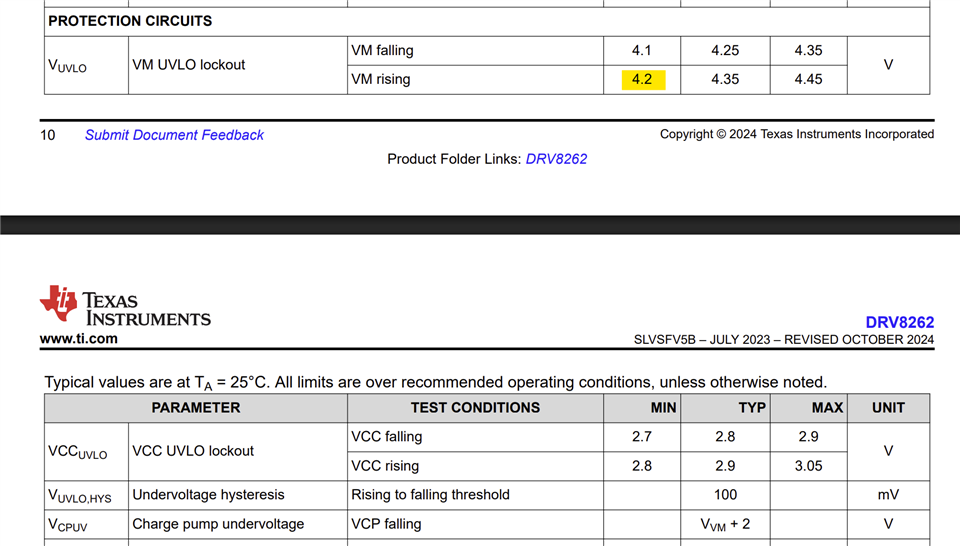

According to the datasheet, I have the following settings:

MODE1 = HIGH → Single H-bridge

MODE2 = LOW → PH/EN interface

This is correct for Single H-bridge and PH/EN control mode.

2. How can I increase VREF correctly?

I would like to increase the maximum current that the DRV8262 can deliver.

The data sheet states that you need to:

remove jumper J6 (to cut the internal connection)

and then apply an external voltage (e.g. 1.5 V or 3.3 V) to J5 (upper pin)

So I removed J6 and applied 3.3 V to J5, but nothing happened .

The coil still draws barely any current, and it seems as if VREF is being ignored or blocked.

For external VREF connection in Single H-bridge mode both VREF1 and VREF2 must be tied together. In the EVM this means open J26 and shunt J25 - see below. Remove J6 to cut VREF2 from the MSP430 DAC. You should apply external VREF voltage 0 to 3.3 V via pin-1 of J7 or J6 or J5. You had this correct. Perhaps the missing piece was J25 shunt (remove J26).

observation

If I set MODE2 = HIGH for testing purposes (i.e. put the driver into IN/IN mode),

the coil receives an output signal – so the driver basically reacts.But never more than about 0.5 A flows , even with a supply voltage of 5 V, 9 V or 12 V.

Is this really due to VREF?

Is the current being limited internally because VREF is too low?

Or could something else be responsible?

Which pin on the EVM board is this exactly?

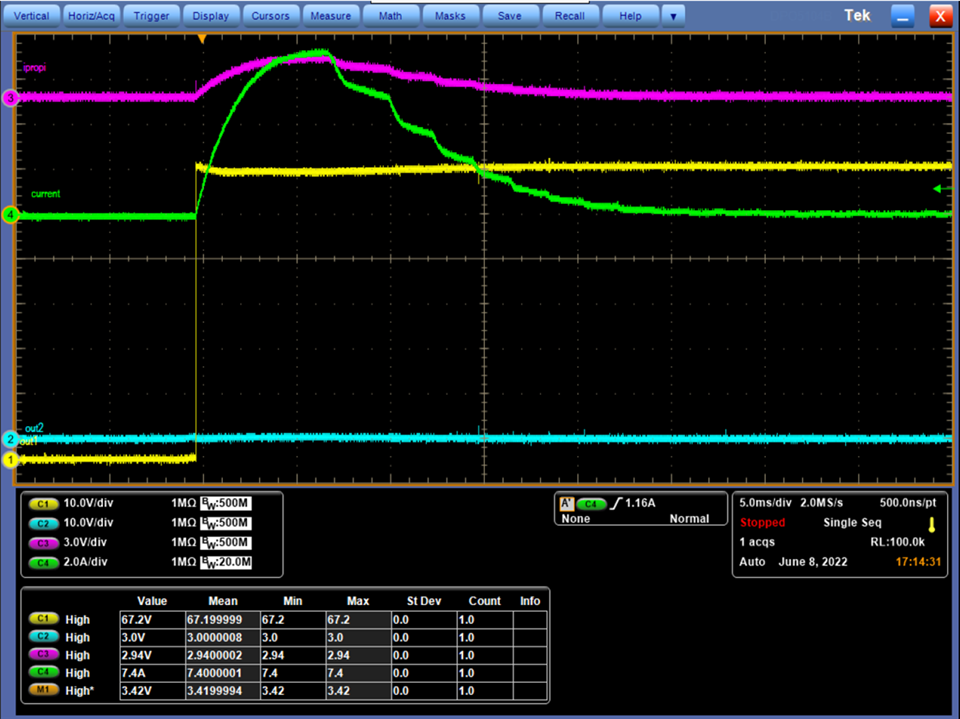

The EVM has two 3.3 kΩ RIPROPI resistors in parallel (1.65 kΩ) after J19 shunt is installed for Single H-bridge operation. See below. With external VREF = 3.3 V (VREF MAX) the current through IPROPI would be 3.3 / 1650 = 2 mA. The specified AIPROPI for this device is 212 μA / A. The output current would be regulated at 2E-3 / 212E-6 = 9.4 A.

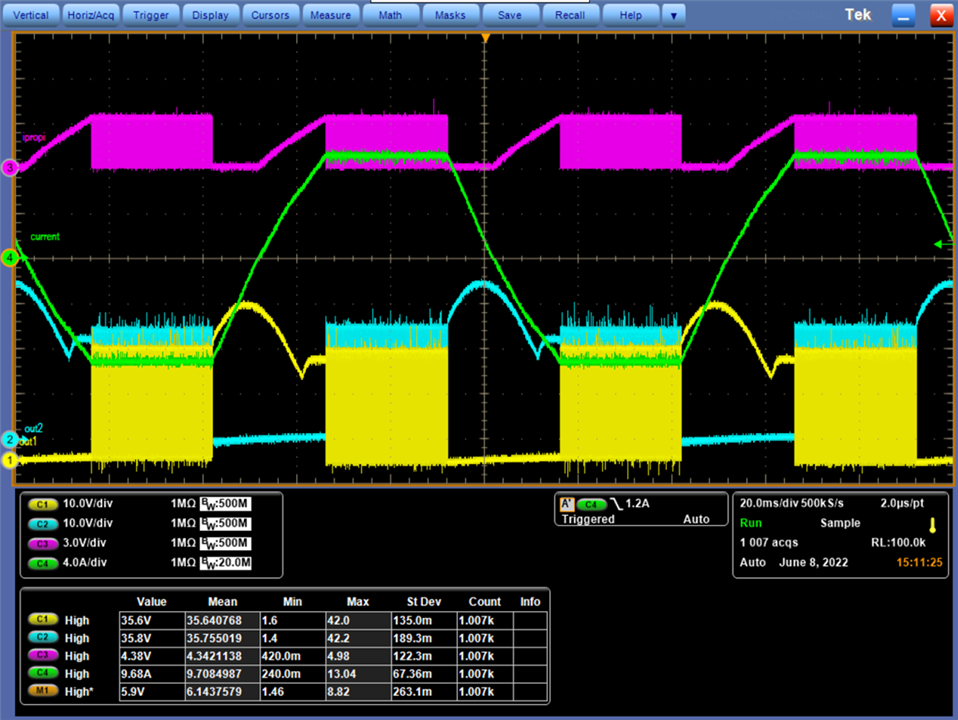

Nachdem ich die Einstellung vorgenommen habe hat sich folgendes Problem ergeben:

Wenn ich an J14 eine Diode anschließe fängt diese an zu leuchten. Ich kann auch die Eingangsspannung beliebig ändern.

Falls ich nun einen E-Motor oder eine Spule, sprich eine hohe Last anschließe, kann ich nicht mehr als 4V Eingangsspannung an J12 einstellen. Sobald ich mehr als 4V einstelle fängt das Board an zu piepsen und die Warnleuchte D7 leuchtet auf.

Deshalb meine Frage wieso funktioniert die Einstellung für geringfügige Lasten, aber bei hohen Lasten bricht das System zusammen?

Besten Dank!

HAL_TIM_PWM_Start(&htim2, TIM_CHANNEL_2);

HAL_TIM_PWM_Start(&htim2, TIM_CHANNEL_2);