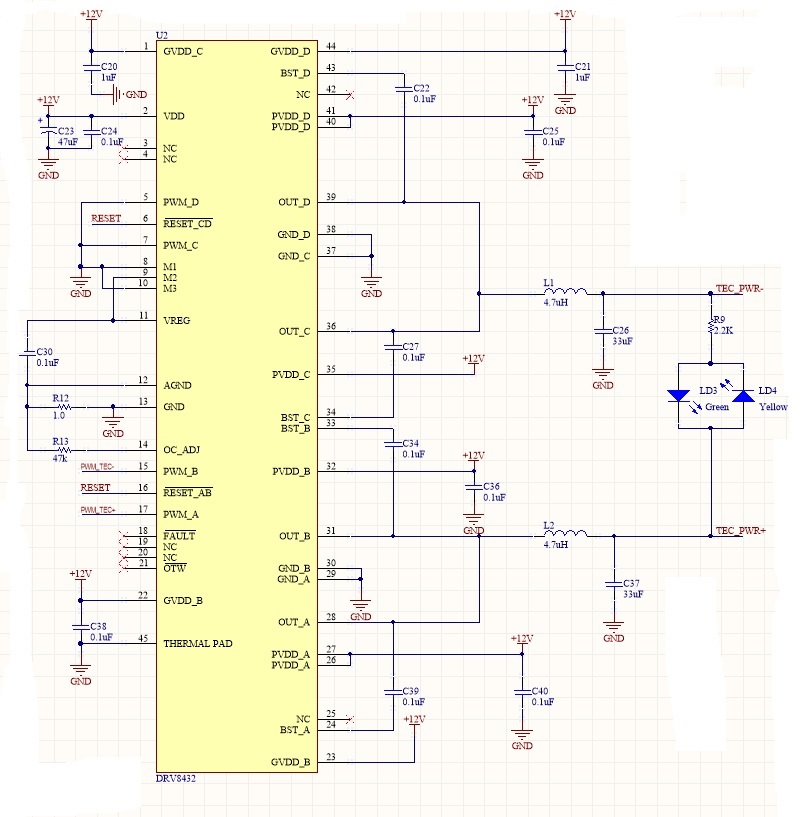

I have a designed a circuit with DRV8412 for TEC which can up to 6A at 12VDC, I have configured it to parallel full mode with LC filter connected at the output. The problem I am facing is that DRV8412 is heating a lot even without load, with several experiments I observed that when I keep the switching frequency of PWM signal fs<100kHz it start heating, with fs<10kHz the DRV8412 does not work at all, the output is 0.2VDC. What might be the problem? How can I solve this problem?

-

Ask a related question

What is a related question?A related question is a question created from another question. When the related question is created, it will be automatically linked to the original question.