Other Parts Discussed in Thread: DRV8833, DRV8833C

our customer one project need control gate to open or close on some occasion. Recently, encounter a problem in utilizing DRV8832 chip-set to control gate. The detailed information is as follows.

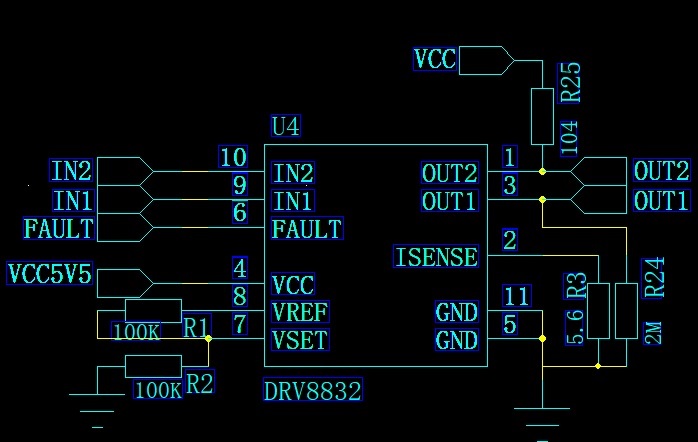

Background: Because of small stall current based on the adopted gate, 100mA or so is expected. According to specification of DRV832, the voltage of “Vset” is designed to half of “Vref”. Therefore, the voltage of output to gate is designed to 2.5V or so. The voltage of “Vcc” is provided by battery, the value spans the range between 6.0v and 4.0v. In order to achieve feedback of “Fault” pin, “Rsense” increases to 5.6 ohm(Ω) with “Vcc” of 6.0v. That seems work well.

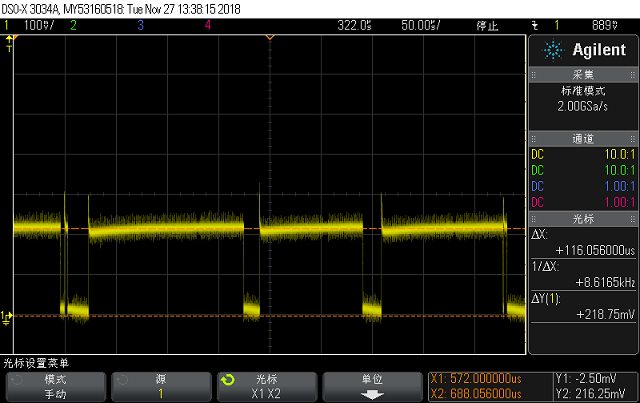

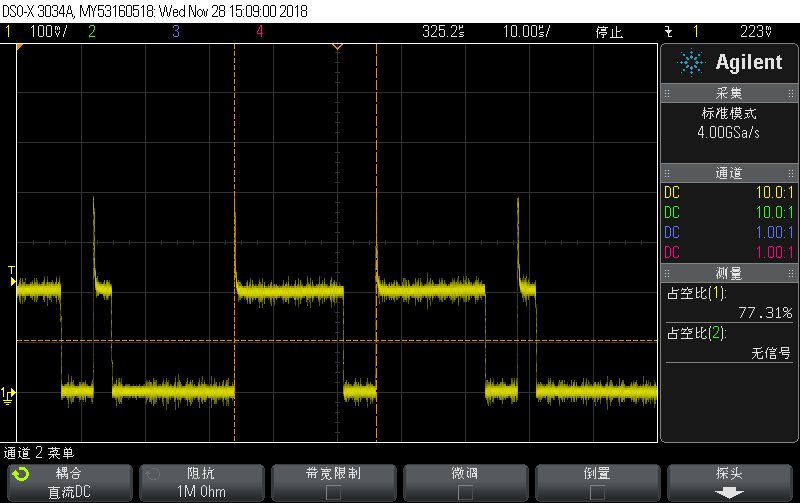

Problem: Further verify closing or opening the gate with lower voltage of “Vcc”, found out that no feedback on “Fault” pin after “Vcc” decrease to 5.0V or less, and mistake this as an exception in closing or opening gate.

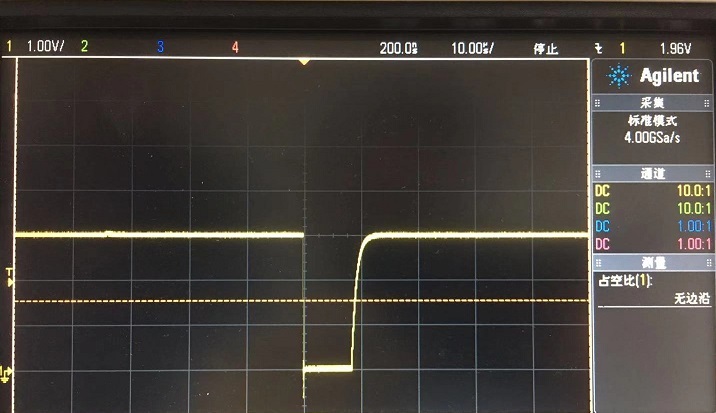

Experiment 1: The motor internal resistance of gate is 25 ohm(Ω) . Based on the hardware configure of “Vcc: 6.0v” mentioned before, the voltage of output is 2.5v or so as expected with zero-load, meanwhile, outout voltage is 0.8v that is unexpected with the gate load. If replacing with “Rsense” of 1 ohm(Ω), the voltage of output seems constant, 2.5v output is expected , regardless of zero load or gate load. That’s weird. Why? (1)

Experiment 2: Based on “Rsense” of 5.6 ohm(Ω), while altering voltage of “Vcc”, the voltage of output seems not constant with gate load. Under the “Vcc” of 5.0v or less, No feedback on “Fault” pin. Why? (2)

Problem: “The resistor used to set the current limit must be less than 1Ω.” , which is cited from the specification of DRV8832. May I have the cause of the requirement? (3)

Solution: Any solution related to the application based on DRV8832? (4)

Looking forward to your feedback related to the four questions Thanks a lots.