Other Parts Discussed in Thread: DRV8323, LAUNCHXL-F28069M, MOTORWARE

Hi,

I am an electrical engineering student designing a 3 phase bldc motor driver circuit mostly based off the DRV8305 typical application data and EVM. I have manufactured a PCB and done the standard electrical continuity tests. My design is mostly based off the typical application circuit and DRV8305EVM with some additional features that are not relevant to this discussion.

I find that the DRV8305 becomes abnormally when it is connected even in an idle state.

Once operating the IC begins to heat excessively to a point where the package is too hot to touch after running the code for barely one second. The mosfets stage stay cool however.

I have no idea how to troubleshoot this problem and my equipment is somewhat limited.

I've read that the IDRIVE settings, TDRIVE settings and Deadtime can be used to adjust the FETs gate current so to prevent overheating but I am still confused of how to chose the IDRIVE and Dead time settings. I read that the Tdrive settings should be about 2 times the rise time of the MOSFETs.

In my case 2x 91ns would be 182ns which is shorter than any of the settings available. So I would chose the lowest setting of 220ns.

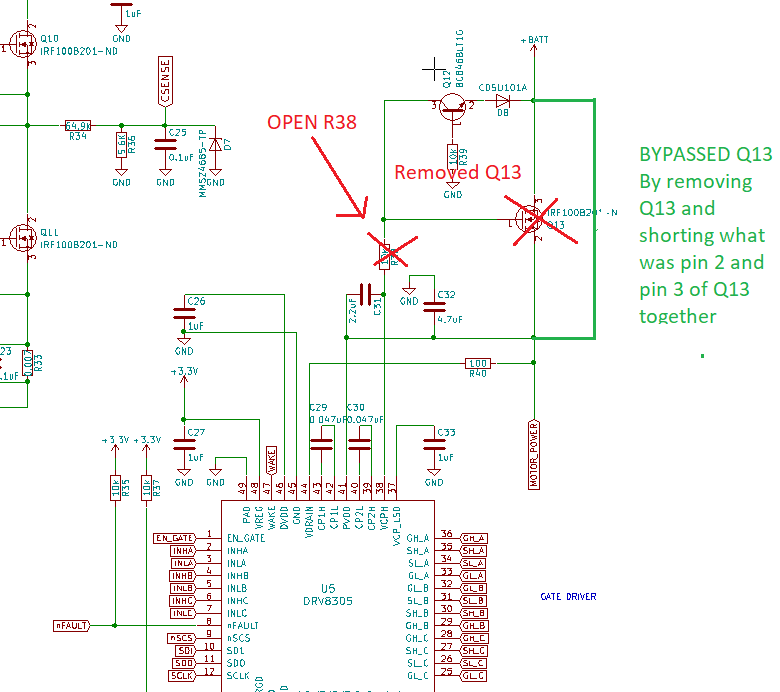

I am attaching my schematic here.

Any help would be appreciated ! :)