Other Parts Discussed in Thread: TPS63030

Hi.

I have a problem with the development of our product, more precisely, with the operation of the AT42QT1012 touch chip.

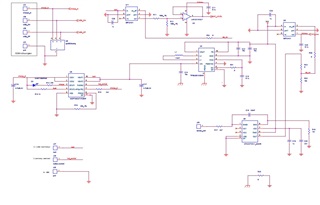

We have our engineering design for a wearable device that has an AT42QT1012 Touch sensor chip. All-time MCU, LCD is disabled. The user can enable the device by the touch sensor. After enabling the system must shut down by itself within 15 minutes (+-10% according to datasheet).

The problem is that the current design doesn't work stably: the device is enabled by itself: when I leave the system on the table, the PCBA is connected to the battery, without any action, or put it on the charge, periodically, the touch turns on and off itself, without my participation.

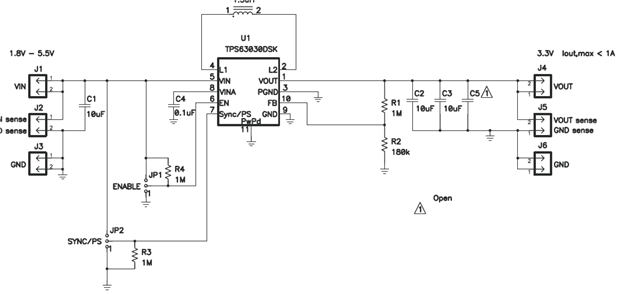

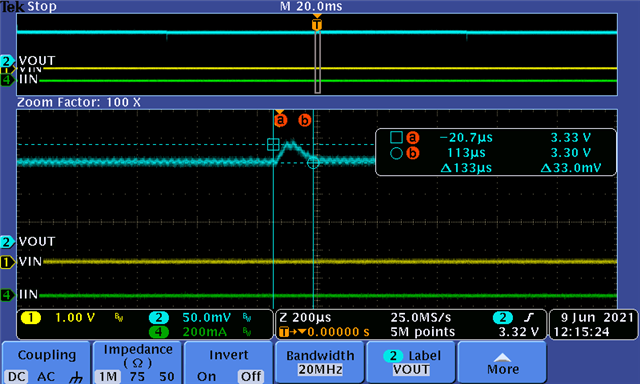

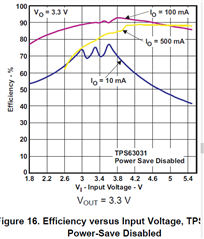

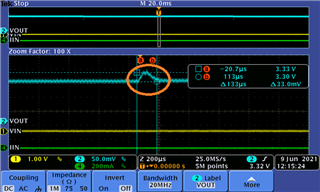

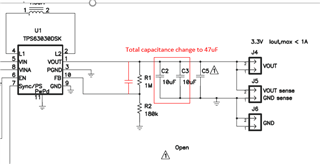

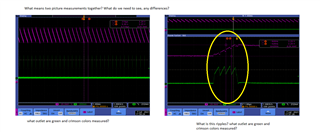

In our previous PCB design, the touch worked perfect, but the DC / DC consumed a lot of current. We corrected the design of the DC / DC connection (like described in this post: https://e2e.ti.com/support/power-management/f/196/t/962067), added several resistors '0' so that it was possible to disconnect components from the PCB. Now DC / DC does not consume current, but the touch began to turn on / turn on itself. In the previous PCB design the DCDC out was like an attached image 2 all time.

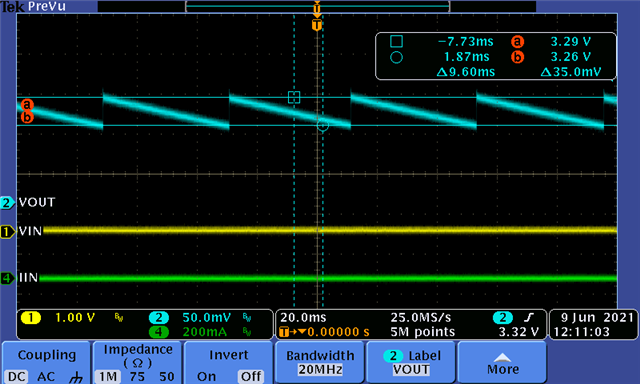

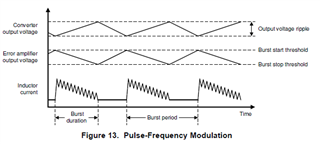

But now, when the DCDC is in "Power Saving Mode", it works like an attached image 1.

When touch is "ON" and the system starts operation, the DCDC outputs exactly 3.3 volts DC, like an attached image 2.

This answer I have received from Microchip:

"If there is considerable noise in the power supply, such behavior can be observed. As the touch technology charges the sensor and measures the charge stored, any fluctuation in the voltage during this charging and measuring process can affect the signal values which can be similar to a touch (that changes capacitance).

Hence such false detects could occur."

How can I resolve this issue and equalize the voltage: remove the waves?

Attached my power management side schematic:

Thanks

Evgeni