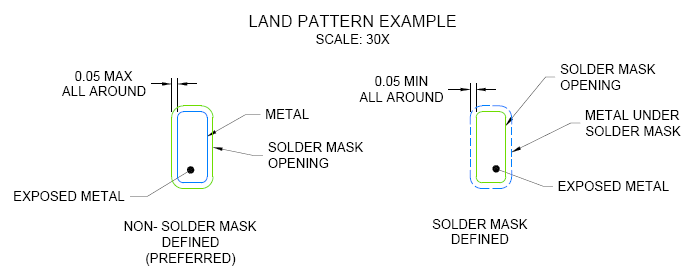

It doesn't look like the Altium UltraLibrarian footprint for the TPS25947 has been fixed. The datasheet shows the correct solder mask information. In the Altium UltraLibrarian footprint, the solder mask is exactly the same size as the copper pads. Here are some screenshots:

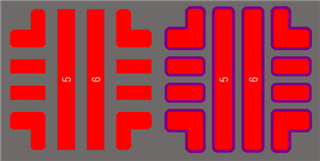

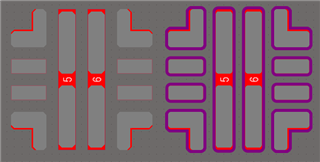

The UltraLibrarian footprint is on the left, and what it should look like is on the right.

Copper pads, with solder mask in the background:

Solder mask only:

Copper, solder mask, and paste layers:

Greg