Hello,

We have built a PCB using TPS259827 ( referenced thread on E2E : https://e2e.ti.com/support/power-management-group/power-management/f/power-management-forum/834947/tps25982-soa-and-max-cout -> " there is no limit on the amount of Cout. You can increase dv/dt capacitor value to reduce Vout slew-rate (and hence inrush currents) to support large Cout")

From this referenced thread, my understanding was that by adding appropriate C to Cdvdt, large Cout would be applicable.

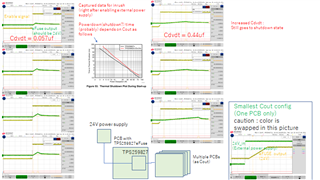

We've built our board using TPS259827 and found that there are critical problem during start-up depends on load (another PCBs) connected after TPS259827.

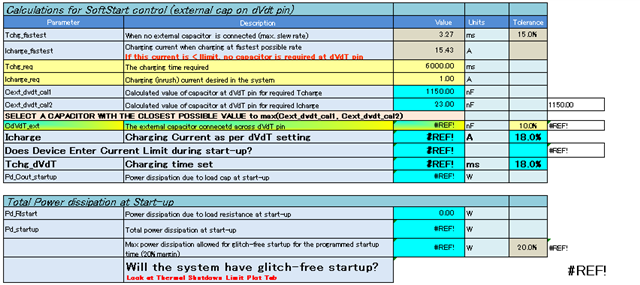

After these evaluation, I've found TPS25982xx_Design_Calculator_RevA.xlsm on TI website.

It seems that it is really difficult(almost impossible) to use large Cout with 24V using TPS259827 due to "Thermal Shutdown Plot During Start-up" (datasheet Figure 53.)

From TPS25982xx_Design_Calculator_RevA.xlsm, it seems that ~1mF is maximum Cout value for Tchg_req 200ms and 2.5mF with Tchg_req 2000ms.

Our system requirement:

- Vin typ. 24V, Vout 24V

- Cout ~5mF ( Total capacitance on PCBs connected after TPS259827 )

- There are multiple bypass capacitors (before circuits) on PCBs connected after TPS259827. Total C amount ~ 5mF

- 10+ [A] continuous after start-up as normal operation, ILIM 15 [A]

- Used as 24V switch, part of power-on sequence

Question :

(1) Are there any kind of solution to solve current issue using TPS259827?

(2) Are there any kind of alternatives?

Best Regards,

Ryo