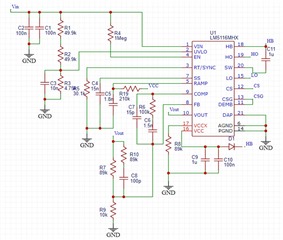

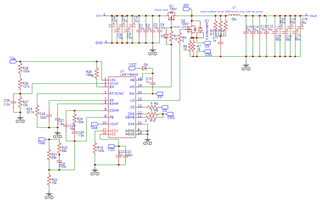

Hello, the full description of my problem is attached in a pdf file. also attached is the schematic of my LM5116 peripherals.

In summary: When stuck in hard short, sometimes while retrying into hiccup mode - the controller will lose current sense and the inductor current will be unlimited.

Please read the pdf for a full description.

Thanks!