Other Parts Discussed in Thread: TL431, , LM5021

Hi there,

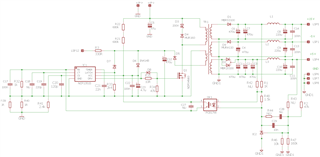

I am willing to design similar product for diffirent input range, https://www.ti.com/tool/UCC28740EVM-525

INPUT: 250 to 650 VDC

OUTPUT: 24V/5A

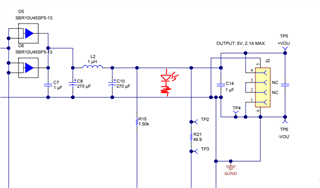

Kindly suggest me to change the schematics ( reffrence design from above link) below,

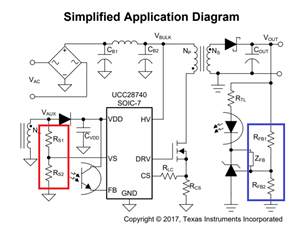

1. I want to remove the input bridge diode part, could you tell me does D4 and D3 has include for AC input in primatry side of transformer ?

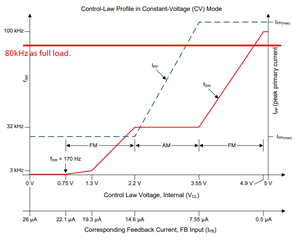

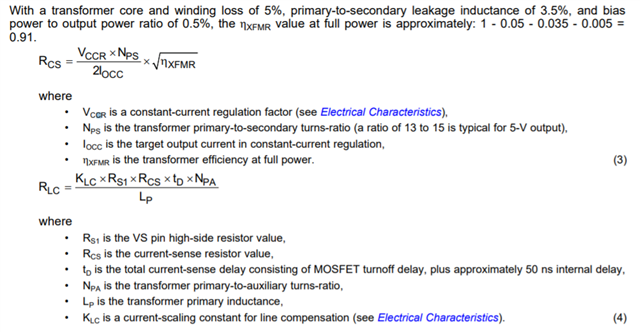

2. My input may vary from 250 to 650 VDC, so R2, R3 value should keep according to equation 1 and 2 of datasheet UCC28740? Does it mean input range should be fixed ?

3. My MOSFET should be 900VDC, how about change it to TU7NM90N?

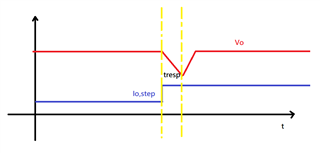

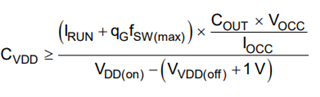

4. Explain to change C6 value.

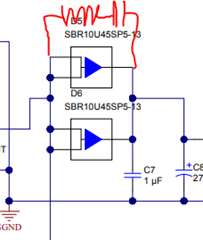

5. Suggest to calculate output inductor and capacitors , C7,C8, L2,C10, C14,C15.

6. Describe to calculate protection circutity C12,R8, C13.

7. By the voltage divider rules, R2-R21 has been calculate right?

8. to sencing the R16 value, LTV -817 is okay for 24V/5A application?